A purge stream often is included in recycle plants, such as the reactor/flash plan discussed in this

Question:

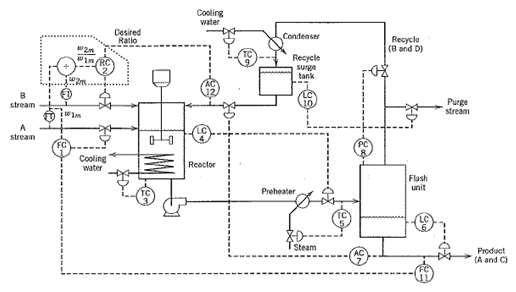

A purge stream often is included in recycle plants, such as the reactor/flash plan discussed in this chapter, to keep the concentration of a contaminant from building up within the plant. Thus, one might conclude that the best way to control the concentration of the contaminant below some acceptable level would be to manipulate the purge stream flow rate, i.e., w6. Examine whether such an approach will work well here, using the following approach:(a) Modify the Simulink program of the reactor/flash unit core model so it includes an x8D- w6 loop and an HT-R loop along with the remaining two loops summarized in Table E.2.8. Thus each of the new controllers so as to obtain a low level of interaction with the other control loops.(b) What features in the RGA analysis given in Eq. 24.2 or in the discussion in the first two para-graphs of Section 24.4 explain the response results for your alternative control structure, when compared to those shown in Figure?(c) Can you give a physical explanation for the observed process gain between X8D andW6(d) How would you expect the plant to respond if one of the control loops was inoperable, e.g., as a result of a sensor failure? Remove the X4A-W8 control loop and compare the structure presented in this problem with the RGA suggested pairing for a +5% step change in production rate.(e) How well do these two control structures (with all loops dosed) handle a larger set-point change (10%) in the production rate, W4? in particular, what modifications (if any) mast be made to handle a see-point change of this magnitude? Can a 20% change in w4 be accommodated? Why or whynot?

Step by Step Answer:

Process Dynamics And Control

ISBN: 978-0471000778

2nd Edition

Authors: Dale E. Seborg, Thomas F. Edgar, Duncan A. Mellich