At the beginning of the last quarter of 2013, Youngston, Inc., a consumer products firm, hired Maria

Question:

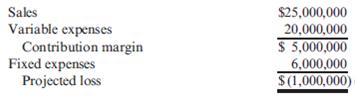

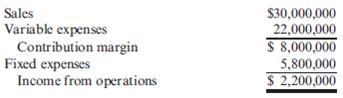

At the beginning of the last quarter of 2013, Youngston, Inc., a consumer products firm, hired Maria Carrillo to take over one of its divisions. The division manufactured small home appliances and was struggling to survive in a very competitive market. Maria immediately requested a projected income statement for 2013. In response, the controller provided the following statement:

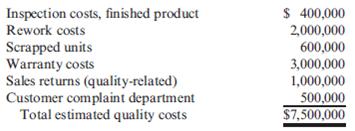

After some investigation, Maria soon realized that the products being produced had a serious problem with quality. She once again requested a special study by the controller’s office to supply a report on the level of quality costs. By the middle of November, Maria received the following report from the controller:

Maria was surprised at the level of quality costs. They represented 30 percent of sales, which was certainly excessive. She knew that the division had to produce high-quality products to survive. The number of defective units produced needed to be reduced dramatically. Thus, Maria decided to pursue a quality-driven turnaround strategy. Revenue growth and cost reduction could both be achieved if quality could be improved. By growing revenues and decreasing costs, profitability could be increased.

After meeting with the managers of production, marketing, purchasing, and human resources, Maria made the following decisions, effective immediately (end of November 2013):

a. More will be invested in employee training. Workers will be trained to detect quality problems and empowered to make improvements. Workers will be allowed a bonus of 10 percent of any cost savings produced by their suggested improvements.

b. Two design engineers will be hired immediately, with expectations of hiring one or two more within a year. These engineers will be in charge of redesigning processes and products with the objective of improving quality. They will also be given the responsibility of working with selected suppliers to help improve the quality of their products and processes. Design engineers were considered a strategic necessity.

c. Implement a new process: evaluation and selection of suppliers. This new process has the objective of selecting a group of suppliers that are willing and capable of providing nonde-fective components.

d. Effective immediately, the division will begin inspecting purchased components. According to production, many of the quality problems are caused by defective components purchased from outside suppliers. Incoming inspection is viewed as a transitional activity. Once the division has developed a group of suppliers capable of delivering nondefective components, this activity will be eliminated.

e. Within three years, the goal is to produce products with a defect rate less than 0.10 percent. By reducing the defect rate to this level, marketing is confident that market share will increase by at least 50 percent (as a consequence of increased customer satisfaction). Products with better quality will help establish an improved product image and reputation, allowing the division to capture new customers and increase market share.

f. Accounting will be given the charge to install a quality information reporting system. Daily reports on operational quality data (e.g., percentage of defective units), weekly updates of trend graphs (posted throughout the division), and quarterly cost reports are the types of information required.

g. To help direct the improvements in quality activities, kaizen costing is to be implemented. For example, for the year 2013, a kaizen standard of 6 percent of the selling price per unit was set for rework costs, a 25 percent reduction from the current actual cost.

To ensure that the quality improvements were directed and translated into concrete financial outcomes, Maria also began to implement a Balanced Scorecard for the division. By the end of 2014, progress was being made. Sales had increased to $26,000,000, and the kaizen improvements were meeting or beating expectations. For example, rework costs had dropped to $1,500,000.

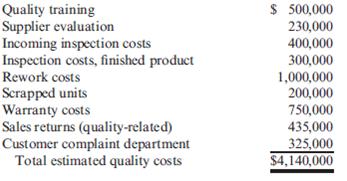

At the end of 2015, two years after the turnaround quality strategy was implemented, Maria received the following quality cost report:

Maria also received an income statement for 2015:

Maria was pleased with the outcomes. Revenues had grown, and costs had been reduced by at least as much as she had projected for the two-year period. Growth next year should be even greater as she was beginning to observe a favorable effect from the higher-quality products. Also, further quality cost reductions should materialize as incoming inspections were showing much higher-quality purchased components.

Required:

1. Identify the strategic objectives, classified by the Balanced Scorecard perspective. Next, suggest measures for each objective.

2. Using the results from Requirement 1, describe Maria’s strategy using a series of if-then statements. Next, prepare a strategy map.3. Explain how you would evaluate the success of the quality-driven turnaround strategy. What additional information would you like to have for this evaluation?4. Explain why Maria felt that the Balanced Scorecard would increase the likelihood that the turnaround strategy would actually produce good financial outcomes.

Contribution margin is an important element of cost volume profit analysis that managers carry out to assess the maximum number of units that are required to be at the breakeven point. Contribution margin is the profit before fixed cost and taxes...

Step by Step Answer:

Cornerstones of Cost Management

ISBN: 978-1285751788

3rd edition

Authors: Don R. Hansen, Maryanne M. Mowen