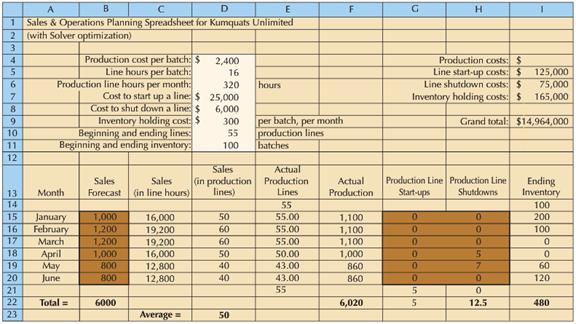

Kumquats Unlimited makes large batches of kumquat paste for use in the food industry. These batches are

Question:

Management has created the following Excel spreadsheet, which uses the Solver function to find the lowest-cost solution to the S&OP problem. Re-create this spreadsheet, including the Solver optimization model (using Example 10.11 as a guide). Your formatting does not have to be the same, but your answers should be. Your spreadsheet should allow the user to make changes only to the planning values, the sales forecast, and the number of production line start-ups and shutdowns. All other values should be calculated. Be sure that Solver does not let inventory drop below zero at the end of any month or end June with less inventory than was available at the beginning of January. To test your spreadsheet, modify the spreadsheet so that each batch requires 32 hours of production line time. The new optimal cost should be $16,215,000.

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Introduction to Operations and Supply Chain Management

ISBN: 978-0132747325

3rd edition

Authors: Cecil B. Bozarth, Robert B. Handfield

Question Posted: