Overall, Steve Edwards, vice president of Marketing at Ditten hoefer's Fine China, is very pleased with the

Question:

Overall, Steve Edwards, vice president of Marketing at Ditten hoefer's Fine China, is very pleased with the success of his new line of Gem-Surface china plates. Gem-Surface plates are different from regular china in that the plates have a special polymer coating that makes them highly resistant to chipping and fading. Not only are the plates more durable, they are also completely dishwasher safe.

In order to manufacture the new plates, Dittenhoefer's has leased a special machine to apply the coating and has put in place a drying system to "cure" the coating on the plates. The research and development (R&D) lab has determined that in order to prevent defective plates, it is important that the ma chine apply the polymer coating at the proper temperature and in the proper thickness. Specifically, R&D has written up the following guidelines:

1. On which dimensions of quality does Dittenhoefer's compete? How are these dimensions being threatened by the problems in the manufacturing and customer service areas?

2. What do you think are the problems with the current manufacturing process as a whole and with the polymer coating machine in particular? How might you use process mapping and root cause analysis to get to the bottom of these problems?

3. Develop a Pareto chart based on the customer survey results for the customer service office. What seem to be the key problems? How might you use the PDCA cycle to go about resolving these problems?

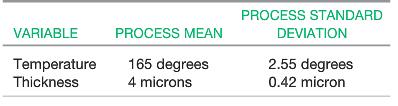

4. Suppose the polymer-coating machine currently provides the following results:

Calculate the process capability ratio (Cp) for both the temperature and thickness variables. Is the polymer- coating process able to meet the engineering standards 99.7% of the time? Explain.

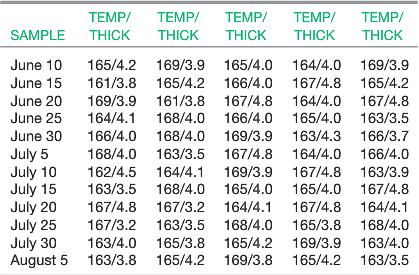

5. After making numerous process improvements, Steve Edwards decides to set up control charts to monitor the temperature and thickness results for the polymer- coating machine. Sample temperature and thickness data are shown in the table on the next page. Set up the appropriate control charts.

Polymer-Coating Machine: Sample Temperature and Thickness Measurements (taken when the process was under control)

Step by Step Answer:

Introduction to Operations and Supply Chain Management

ISBN: 978-0132747325

3rd edition

Authors: Cecil B. Bozarth, Robert B. Handfield