Consider the following batch sequencing problem: Two chemicals A and B are to be produced. Each chemical

Question:

Consider the following batch sequencing problem:

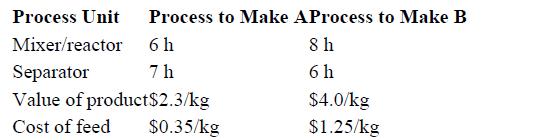

Two chemicals A and B are to be produced. Each chemical requires the use of a mixer/reactor and a separator unit. The amount of each product made in a batch is the same. The times required to make each chemical along with the value of each chemical are given in the table below. Marketing predictions and forecasting suggest that any amount of A can be sold but that a maximum of 250 batches of B can be sold in a year.

Marketing predictions and forecasting suggest that any amount of A can be sold but that a maximum of 250 batches of B can be sold in a year.

Ignoring scheduling issues and assuming that both pieces of equipment can be run for all 8760 hours in a year, determine the optimal mix of Products A and B.

There is virtually no product storage available in the current plant, and once a batch is made it is sent directly to a tank car and shipped out. Can the answer from Part (a) be accommodated taking into account the scheduling of products without intermediate storage and without using single-product campaigns for A and B (see Chapter 3 for a discussion and an explanation of campaigns)? If the answer is no, then determine the optimum schedule and maximum profit.

Would your answers from Parts (a) and (b) change if there were no restriction on the amount of B that could be produced and sold?

Step by Step Answer:

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting