One technique to control the generation of a hot spot at the beginning of a reactor is

Question:

One technique to control the generation of a hot spot at the beginning of a reactor is to load the front end of the reactor with a diluted catalyst and then to load the remainder of the reactor with the undiluted catalyst. For the phthalic anhydride example given in Examples 22.9, 22.10, and 22.11, it has been decided to load the front end of the reactor tubes with a catalyst containing 5% inactive material (f = 0.95) and the remainder with fully active catalyst (f = 1.0). For a 1 m length, 25.4 mm diameter tube, what is the maximum conversion of o-xylene (pA,in = 0.0175 bar) that can be achieved without exceeding the maximum catalyst temperature of 410°C?

Problem 22.10

Reexamine Problem 22.9 for the following cases:

1. Design a packed bed reactor with intercooling (shell-and-tube design)

using a cooling medium with a phase change (Tboil = 350°C) to obtain 80% overall conversion of benzene. Assume that the catalyst tubes have a 2-in diameter and are 3 m in length packed with 5 mm diameter spherical catalyst particles of density 2350 kg/m and voidage = 0.5. The properties of the process gas may be taken as constant with the viscosity as 17 × 10 kg/m/s and the thermal conductivity as 0.0525 W/m/K. For this case, you need to determine the number of tubes needed to give the desired conversion of benzene. For your design, the hot spot in the reactor must not exceed the maximum value of 425°C.

2. Repeat Part (a) above using a process simulator.

Problem 22.9

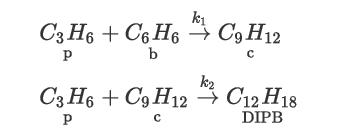

Consider the production of cumene (c) from the catalytic alkylation reaction of benzene (b) using propylene (p)— Reaction 1. A second undesirable reaction (Reaction 2) between propylene and cumene occurs to produce pdiisopropyl benzene (DIPB):

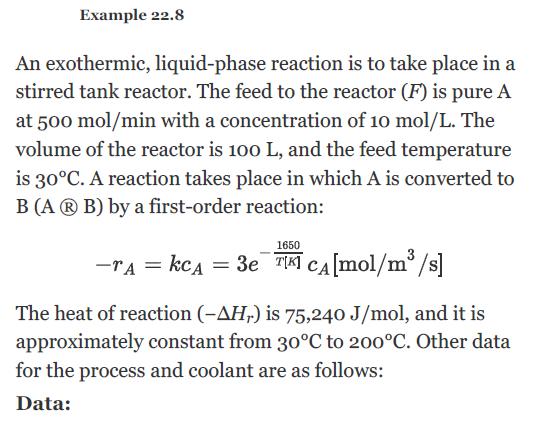

where r1 = k1 cp cb and r2 = k2 cp cb and the rates of reaction are given in mol/L/s and the rate constants are![k = 2.8 x 107 exp = 2.32 x 10 exp k2= 12,530 T[K] and 17,650 170). These reactions are quite](https://dsd5zvtm8ll6.cloudfront.net/images/question_images/1699/4/4/1/388654b6aecae9931699441387138.jpg)

exothermic, and typical reactor temperatures are in the range 350°C to 410°C. The heats of reaction per mol of product in this temperature range are −100.6 kJ/mol and 121.3 kJ/mol for Reactions 1 and 2, respectively. The heat capacities for the reactant and product streams may be taken to be the same and equal to 2.44 kJ/kg/K in this range. For this system, do the following:

1. Determine the conversion of an equimolar feed of propylene and benzene (feed conditions are 350°C, 3 MPa, and 100 mol/s) if the reactor is run as an adiabatic packed bed with a maximum outlet temperature of 425°C.

2. Based on the results from Part (a), is it feasible to obtain an overall conversion of 80% of the benzene using a series of staged packed beds with cooling between stages to bring the temperature back to 350°C at the inlet of the next reactor stage? In practice, no more than four stages would be used.

Problem 22.11

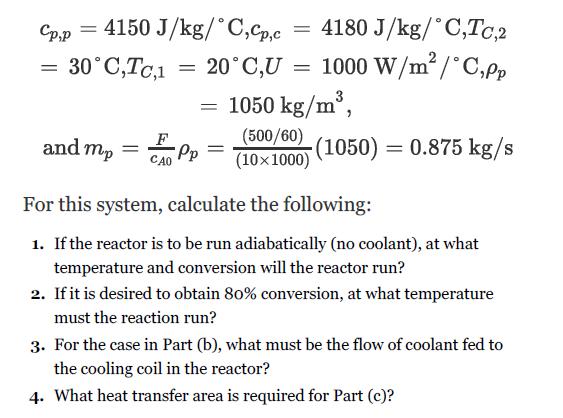

For the stirred tank reactor in Example 22.8, determine whether the chosen operating/design point (T= 93.5, X = 80%, Tc,1 = 20C, TC,2 = 30C, and A = 3.96 m2) represents a stable operating condition.

Step by Step Answer:

Analysis Synthesis And Design Of Chemical Processes

ISBN: 9780134177403

5th Edition

Authors: Richard Turton, Joseph Shaeiwitz, Debangsu Bhattacharyya, Wallace Whiting