With headquarters located in Brantford, Ontario, ASCO Valve Canada is one of Canadas top producers of solenoid

Question:

With headquarters located in Brantford, Ontario, ASCO Valve Canada is one of Canada’s top producers of solenoid valves. The company was founded in 1965, and since that time it has emerged as a successful industrial company that currently employs more than 75 people across Canada. ASCO offers an array of products to its customers ranging from valves that are used in the gas pipeline industry to valves that are used in medical procedures. One of ASCO’s goals was to develop a valve that could minimize the cost to customers, including cost of operations and the amount of power consumed. In 2005, ASCO achieved its goal by developing and introducing its RedHat valves. Today, these valves are well recognized and respected in many different countries due to their exceptional performance in difficult conditions. These valves are also energy efficient because they are able to use a mere 2 watts of power rather than the 17 watts of power that the typical solenoid valves use. This is an important cost benefit for any customer using valves because these new products can decrease the total cost of ownership by almost 14% over the installed life of the valve. The RedHat valves have many advantages: for example, (1) better and more reliable functionality, (2) reduced usage of power, and (3) modular design. These advantages have allowed ASCO to provide customers with better-quality valves at reasonable prices, and to ensure fast delivery. ASCO made it clear that one of its objectives was to reduce lead times in order to satisfy customer demand. Within a short period of time, it accomplished this and can deliver products to its customers at a much faster rate.

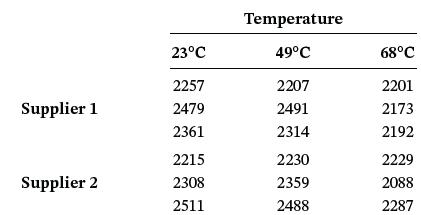

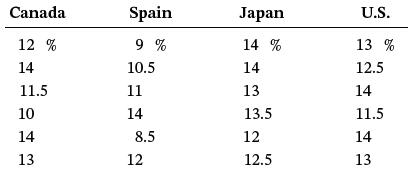

1. The RedHat valves are durable and reliable. They can operate with high air pressure of up to 2,200 psi (pounds per square inch). Suppose ASCO develops a new and stronger version of the RedHat valve. It wants to set up an experimental design to test the strength of the new valve, but it wants to conduct the tests under three different temperature conditions, 23°C, 49°C, and 68°C. In addition, suppose ASCO uses two different suppliers (supplier 1 and supplier 2) for the synthetic materials that are used to manufacture the valves. Some valves are made primarily of raw materials supplied by supplier 1, and some are made primarily of raw materials from supplier 2. Consequently, a 2 × 3 factorial design is appropriate for the experiment, with temperature and supplier as the independent variables and air pressure (measured in psi) as the dependent variable. An appropriate sampling frame has produced the data shown below. Analyze the data and discuss the business implications of the findings. If you were conducting the study, what conclusions would you report to the company? 2. It is estimated that these RedHat energy-efficient valves can save a great deal of power usage and lower the total cost of ownership by up to 14% over the installed life of the valve, therefore making the RedHat valves more attractive. ASCO does business with pipeline companies globally. In an attempt to position itself as a market leader across the world, ASCO is keen on finding out whether the cost saved over the installed life of the valve is significantly different among the different countries in which it does business. Four countries, Canada, Spain, Japan, and the United States, are chosen for the study. Pipeline companies are selected from each country. The companies keep a log of valve power usage. A random sample of the data is shown below. Test whether there is a difference in relative cost savings in each of these countries. Justify your answer and prepare a short report to present to the management of ASCO in which your conclusions are explained, with support from the statistical test that you performed.

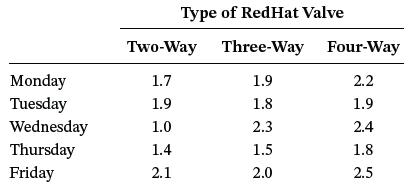

2. It is estimated that these RedHat energy-efficient valves can save a great deal of power usage and lower the total cost of ownership by up to 14% over the installed life of the valve, therefore making the RedHat valves more attractive. ASCO does business with pipeline companies globally. In an attempt to position itself as a market leader across the world, ASCO is keen on finding out whether the cost saved over the installed life of the valve is significantly different among the different countries in which it does business. Four countries, Canada, Spain, Japan, and the United States, are chosen for the study. Pipeline companies are selected from each country. The companies keep a log of valve power usage. A random sample of the data is shown below. Test whether there is a difference in relative cost savings in each of these countries. Justify your answer and prepare a short report to present to the management of ASCO in which your conclusions are explained, with support from the statistical test that you performed. 3. As previously mentioned, ASCO has been able to reduce its lead time. Suppose ASCO’s original lead time averaged 10 weeks and that the reduction is in the neighbourhood of 80%. As such, most lead times now average slightly below two weeks. ASCO is interested in knowing whether lead times differ significantly according to the type of RedHat valve it is manufacturing. To control the experiment, it will use as a blocking variable the day of the week the valve was ordered. One lead time was selected per valve per day of the week. The sample data are given below in weeks. Analyze the data and discuss your findings.

3. As previously mentioned, ASCO has been able to reduce its lead time. Suppose ASCO’s original lead time averaged 10 weeks and that the reduction is in the neighbourhood of 80%. As such, most lead times now average slightly below two weeks. ASCO is interested in knowing whether lead times differ significantly according to the type of RedHat valve it is manufacturing. To control the experiment, it will use as a blocking variable the day of the week the valve was ordered. One lead time was selected per valve per day of the week. The sample data are given below in weeks. Analyze the data and discuss your findings.

Step by Step Answer:

Business Statistics For Contemporary Decision Making

ISBN: 9781119577621

3rd Canadian Edition

Authors: Ken Black, Ignacio Castillo