A food processing company is designing the packaging for a new product line of potato chips. The

Question:

A food processing company is designing the packaging for a new product line of potato chips. The expected shelf life of the potato chips is 10 months. The bag has to hold \(200 \mathrm{~g}\) of potato chips and \(1,500 \mathrm{~mL}\) of nitrogen. The nitrogen gas is used as a cushion to prevent crushing the chips and to avoid lipid oxidation. The oxygen level in the bag should be less than \(1 \%\) (Paik et al., 1994).

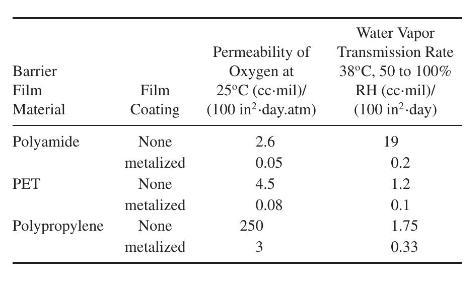

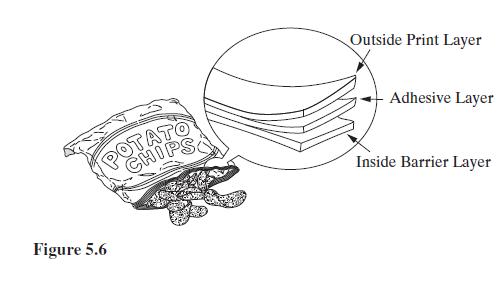

(a) The packaging generally involves three layers, each of which is made up of a few films (Figure 5.6). The outside layer is used for printing. The inside layer serves as the barrier to gas, moisture, and light and provides stiffness and heat seal. The middle layer bonds the outside and inside layers together. One of the films of the inside layer is usually aluminum coated by vaporization on a polymer film. The oxygen flux, \(J\), through

the barrier film is governed by Fick's law,

\[J=P \frac{\Delta p}{L}\]

where \(P\) is the permeability, \(p\) the pressure, and \(L\) the barrier film thickness. The accompanying table shows the permeability to oxygen of a neat polymer film as well as one with metal coating (Tock, 1983). Select with explanations the material you would use for the new packaging design. Note that the cost of materials is a major consideration in snack food packaging and the cost data can be found on the Internet.

(b) What should be the dimensions of the bag? Assuming a constant permeability, calculate the minimum thickness of the selected barrier film to achieve a 10-month shelf life with respect to oxygen (i.e., retaining an oxygen concentration less than \(1 \%\) inside the bag).

(c) Moisture content of the potato chips is another crucial parameter. Assume that the initial moisture content of potato chips is \(1.5 \mathrm{wt} \%\) and should not exceed \(2.5 \mathrm{wt} \%\) at the end of shelf life. Is the barrier film chosen in part

(b) sufficient for the desired product performance with respect to moisture content? The data for moisture flux per unit film thickness in the table can be assumed to be constant within the stated range of \(\mathrm{RH}\).

Figure 5.6:-

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng