Design a process for the separation of (1,000 mathrm{kgmol} / mathrm{hr}) of a mixture comprising (50 mathrm{~mol}

Question:

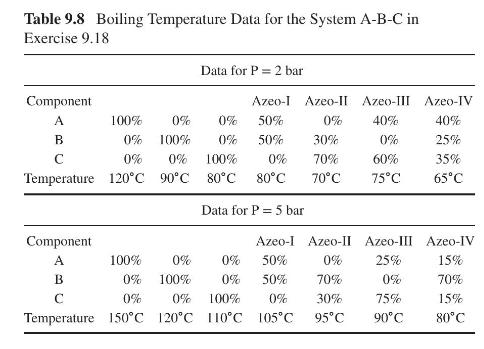

Design a process for the separation of \(1,000 \mathrm{kgmol} / \mathrm{hr}\) of a mixture comprising \(50 \mathrm{~mol} \%\) A and \(50 \mathrm{~mol} \% \mathrm{~B}\) to highly pure product streams (at least \(99 \mathrm{~mol} \%\) each). Your design should consist of at most two columns, with each column having only two product streams (distillate and bottoms), operating at either 2 or 5 bar. You may consider the usage of entrainer C. Boiling temperature data for the system A-B-C is provided in Table 9.8 for the two possible operating pressures.

(a) Design a separation process for the production of highly pure \(\mathrm{A}\) and B (each at least \(99 \mathrm{~mol} \%\) ). Sketch the operating lines for your process on a ternary phase diagram and provide a PFD indicating key compositions and temperatures.

(b) If your solution includes the usage of entrainer \(\mathrm{C}\), estimate the required feed rate of \(\mathrm{C}\) in \(\mathrm{kgmol} / \mathrm{hr}\).

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng