Revamp of a toluene hydrodealkylation process. This problem considers some waste-minimization concepts involving recycle to extinction -

Question:

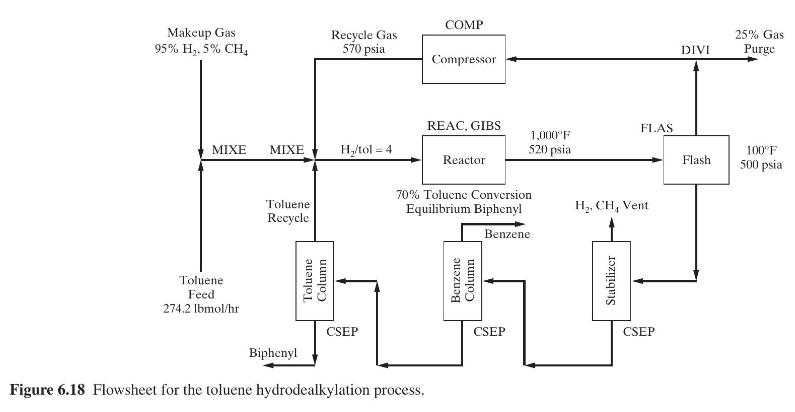

Revamp of a toluene hydrodealkylation process. This problem considers some waste-minimization concepts involving recycle to extinction - a heuristic for process synthesis. However, in this exercise, when this heuristic is applied, analysis using process simulation is carried out. For this reason, we advise the reader to solve this exercise after studying Chapter 7 and possibly after solving which simulates sections of the toluene hydrodealkylation process. Our operating toluene hydrodealkylation unit, shown in Figure 6.18, involves the hydrogenation of toluene to benzene and methane. An equilibrium side reaction produces a small quantity of biphenyl. To be more competitive and to eliminate waste, the process needs to be studied for a possible revamp. The customer for our small production of biphenyl

has informed us that it will not renew its contract with us, and we have no other prospective buyer for biphenyl. Also, a membrane separator company believes that if we install their equipment, we can reduce our makeup hydrogen requirement. Make preliminary process design calculations with a simulator to compare the following two alternatives, and advise me of the technical feasibility of the second alternative and whether we should consider such a revamp further. For your studies, you will have to perform mainly material balance calculations. You will not make detailed distillation calculations, and liquid pumps need not be modeled. For the second alternative, calculate the required area in square feet of the membrane unit and determine if it is reasonable.

Alternative 1. Do no revamp and use the biphenyl for its fuel value.

Alternative 2. Eliminate operation of the toluene column and recycle the biphenyl (with the toluene) to extinction. This should increase the yield of benzene. Also, install a membrane separation unit to reduce hydrogen consumption.

Current plant operation: The current plant operation can be adequately simulated with CHEMCAD, using the equipment models indicated in the flow diagram. Alternatively, any other simulator can be used with appropriate models. Note that the flow diagram of the process includes only the reactor, separators, and recycle-gas compressor. The plant operating factor is \(96 \%(8,410 \mathrm{hr} / \mathrm{yr})\). The feedstock is pure toluene at a flow rate of \(274.2 \mathrm{lbmol} / \mathrm{hr}\), which is fixed for both alternatives, because any additional benzene that we can make can be sold. The makeup hydrogen is \(95 \mathrm{~mol} \%\) hydrogen and \(5 \mathrm{~mol} \%\) methane. Our reactor outlet conditions are \(1,000^{\circ} \mathrm{F}\) and 520 psia. The hydrogen-to-toluene molar ratio in the feed to the reactor must be 4 to prevent coke formation. The toluene conversion is \(70 \%\). The biphenyl in the reactor effluent is the chemical equilibrium amount. The flash drum conditions are \(100^{\circ} \mathrm{F}\) at \(500 \mathrm{psia}\). The flash vapor is not separated into hydrogen and methane but is purged to limit methane buildup in the recycle gas. The purge gas, which has fuel value, is \(25 \%\) of the vapor leaving the flash vessel. Perfect separations can be assumed for the three columns. Based on this information, you can obtain the current plant material balance.

Alternative 1. Simulate the current plant operation. Note that the process has two recycle loops that must be converged. The SRK equation of state is adequate for \(K\)-values and enthalpies. From your converged material balance, summarize the overall component material balance in pounds per year (i.e., process feeds and products).

Alternative 2. Eliminate the toluene column and rerun the simulation. Because the biphenyl will be recycled to extinction, the benzene production should increase. Replace the stream divider, which divides the flash vapor into a purge and a gas recycle, with a membrane separation unit that can be modeled with a CSEP (black-box separator) unit.

For Alternative 2, the vendor of the membrane unit has supplied the following information:

Hydrogen will pass through the membrane faster than methane. Vapor benzene, toluene, and biphenyl will not pass through the membrane. The hydrogen-rich permeate will be the new recycle gas. The retentate gas will be used for fuel. Tests indicate that the purity of the hydrogen-rich permeate gas will be \(95 \mathrm{~mol} \%\) with a hydrogen recovery of \(90 \%\). However, the pressure of the permeate gas will be \(50 \mathrm{psia}\), compared to \(500 \mathrm{psia}\) for the recycle gas in the current plant operation. A pressure of \(570 \mathrm{psia}\) is required at the discharge of the recycle-gas compression system. Thus, a new compressor will be needed.

Run the revamped process with the simulator. From your converged material balance, summarize the overall component material balance in pounds per year (i.e., process feeds and products).

The membrane unit is to be sized by hand calculations on the basis of the hydrogen flux through the membrane. Tests by the vendor using a nonporous cellulose acetate membrane in a spiral-wound module indicate that this flux is \(20 \mathrm{scfh}\left(60^{\circ} \mathrm{F}\right.\) and \(\left.1 \mathrm{~atm}\right)\) per square foot of membrane surface area per 100 psi hydrogen partial-pressure driving force. To determine the driving force, take the hydrogen partial pressure on the feed side of the membrane as the arithmetic average between the inlet and the outlet (retentate) partial pressures. Take the hydrogen partial pressure on the permeate side as that of the final permeate.

Summarize and discuss your results in a report and make recommendations concerning cost studies.

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng