The demand for styrene monomer continues to increase. Other companies produce styrene by alkylating benzene with ethylene

Question:

The demand for styrene monomer continues to increase. Other companies produce styrene by alkylating benzene with ethylene to ethylbenzene, followed by dehydrogenation to styrene. Our chemists have developed a new reaction path to styrene that involves other chemicals that appear to be available from our own supplies at a relatively low cost. These chemicals are toluene and methanol. We have been asked to prepare a preliminary design and economic evaluation for this new route to determine whether it merits further consideration. If so, we will consider entering the styrene manufacturing business.

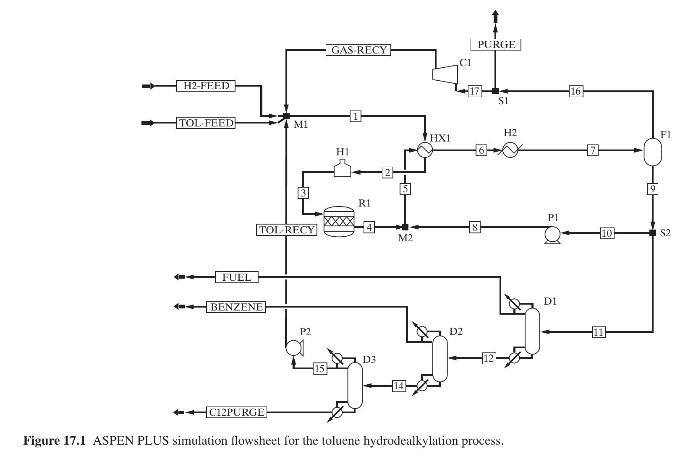

The new process can be broken down into four sections: (1) the reactor section where toluene is partially reacted with methanol to produce styrene, water, and hydrogen, with an unfortunate side reaction that produces ethylbenzene and water; (2) an aqueous stream separation system; (3) an organic stream separation system; and (4) a vapor separation system. Fortunately, we have a potential buyer for the ethylbenzene byproduct. We are assigning you the design and economic calculations of just the organic stream separation system. Others are preparing the designs for the other three sections.

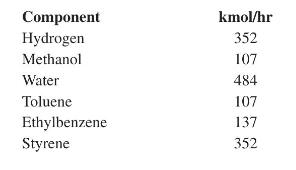

The chemical engineer working on the reactor section has already calculated the following reactor effluent:

This effluent is cooled to \(38^{\circ} \mathrm{C}\) and enters a flash-decanter vessel at \(278 \mathrm{kPa}\). Three phases leave that vessel. The vapor phase (hydrogen rich) is sent to the vapor separation system. The aqueous phase (mostly water with some methanol) is sent to the aqueous stream separation system. The organic-rich phase is sent to the organic stream separation system, which you will design. To obtain the composition of the feed to your section, use a simulator with the UNIFAC method to perform a three-phase flash for the above conditions. If the resulting organic liquid stream contains small amounts of hydrogen and water, assume they can be completely removed at no cost before your stream enters your separation section.

Your separation system must produce the following streams with two distillation operations in series:

A methanol-toluene-rich distillate stream for recycle back to the reactor. This stream should not contain more than \(5 \mathrm{wt} \%\) of combined ethylbenzene and styrene.

An ethylbenzene byproduct stream containing \(0.8 \mathrm{wt} \%\) max. toluene and \(3.9 \mathrm{wt} \%\) max. styrene.

A styrene product stream containing 300 ppm (by wt) max. ethylbenzene.

We have a serious problem with styrene. If any stream contains more than \(50 \mathrm{wt} \%\) styrene, the temperature of the stream must not exceed \(145^{\circ} \mathrm{C}\). Otherwise, the styrene will polymerize. This must be carefully considered when establishing the operation conditions for the two distillation operations. You may have to operate one or both columns under vacuum. This will require you to estimate the amount of air that leaks into the vacuum columns and select and cost vacuum systems. In designing the distillation system, you are to consider the direct sequence and the indirect sequence.

Please submit a report on the two designs and cost estimates (fixed capital and utility operating costs only). For the capital cost of each of the two alternative sequences, sum the purchase costs of the distillation columns, heat exchangers, and any vacuum equipment. Multiply that cost by the appropriate Lang factor. To annualize the capital cost, multiply by 0.333 . Add to this annualized cost the annual utility cost for steam and cooling water. Call this the total annualized cost for the alternative.

Use a simulator to do as many of the calculations as possible, including the very important column pressure-drop calculations (because of the need for vacuum in one or more columns). Assume a condenser pressure drop of \(5 \mathrm{kPa}\) and no pressure drop across the reboiler. You may select column internals from the following list:

Sieve trays on 18 -in. spacing with overall tray efficiency of \(75 \%\).

Pall rings random packing with \(\mathrm{HETP}=24\) in.

Mellapak structured packing with HETP \(=12\) in.

Submit your results as a short report complete with an introduction to the problem, a process description, process flow diagram, discussion of equipment operating conditions and how you arrived at them, a material-balance table, cost tables, conclusions, and your recommendations. Make it clear which alternative you favor and whether it might offer some technical challenges if it is selected for final design.

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng