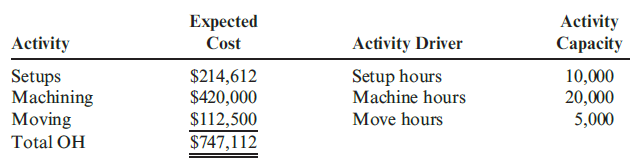

Gee Manufacturing produces two models of camshafts used in the production of automobile engines: Regular and High

Question:

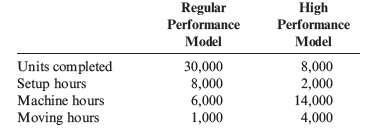

At practical capacity, the expected activity demands for each product are as follows:

The production cycle time for the regular performance camshaft is 0.50 (hours per unit) and that of the high performance camshaft is 2.5 (hours per unit).

Required:

1. Calculate the consumption ratios for each activity. Use these consumption ratios to assign the total overhead to each camshaft model and then calculate the overhead cost per unit for each model (round unit cost to two decimal places).

2. Calculate the total and per unit overhead assigned to each model using DBC (assume you only know cycle time, total overhead costs, and units at practical capacity). Round the overhead rate to four decimal places and the per unit overhead cost to two decimal places. How do the cost assignments compare to those of ABC?

3. Explain to Gee why DBC might be a better choice for assigning overhead costs.

Step by Step Answer:

Cornerstones of Cost Management

ISBN: 978-1305970663

4th edition

Authors: Don R. Hansen, Maryanne M. Mowen