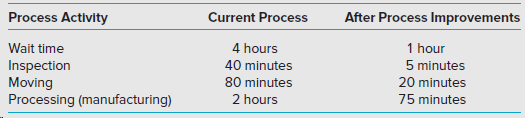

ABC Mfg. is evaluating the desirability of implementing process improvements and is seeking your help in determining

Question:

Required

1. Determine the manufacturing (production) lead time (in minutes) for each of the two decision alternatives.

2. Determine the manufacturing cycle efficiency (MCE) for each decision alternative. (Round decimal answers to 2 places, e.g., 0.3143 = 0.31.)

3. Calculate (to 2 decimal places each) the following: (a) the percentage improvement in MCE, new vs. old, and (b) the ratio of the new manufacturing lead time to the old manufacturing lead time, in decimal form (e.g., 0.4275 = 0.43).

4. Based on only the figures calculated in requirements 1, 2, and 3, should the company implement the proposed process improvements? Why or why not?

5. Why would process improvements, such as those referenced above, likely lead to improved financial results?

Step by Step Answer:

Cost Management A Strategic Emphasis

ISBN: 9781259917028

8th Edition

Authors: Edward Blocher, David F. Stout, Paul Juras, Steven Smith