The control of a positioning device may be achieved using a servomotor, which is a motor designed

Question:

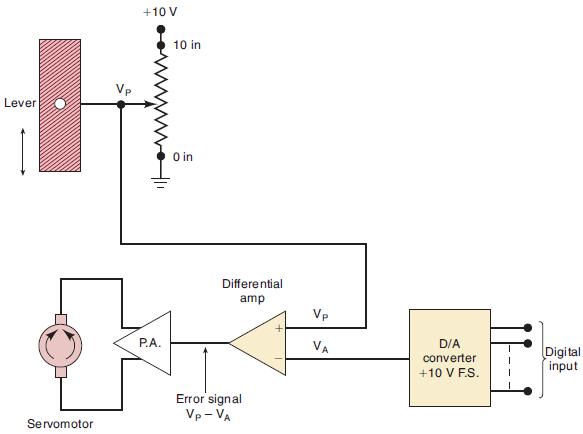

The control of a positioning device may be achieved using a servomotor, which is a motor designed to drive a mechanical device as long as an error signal exists. Figure 11-35 shows a simple servo- controlled system that is controlled by a digital input that could be coming directly from a computer or from an output medium such as magnetic tape. The lever arm is moved vertically by the servomotor. The motor rotates clockwise or counterclockwise, depending on whether the voltage from the power amplifier (P.A.) is positive or negative. The motor stops when the P.A. output is 0.

The mechanical position of the lever is converted to a DC voltage by the potentiometer arrangement shown. When the lever is at its 0 reference point, VP = 0 V. The value of VP increases at the rate of 1 V/inch until the lever is at its highest point (10 inches) and VP = 10 V. The desired position of the lever is provided as a digital code from the computer and is then fed to a DAC, producing VA. The difference between VP and VA (called error) is produced by the differential amplifier and is amplified by the P.A. to drive the motor in the direction that causes the error signal to decrease to 0—that is, moves the lever until VP = VA.

(a) If the lever must be positioned within a resolution of 0.1 in, what is the number of bits needed in the digital input code?

(b) In actual operation, the lever arm might oscillate slightly around the desired position, especially if a wire-wound potentiometer is used. Can you explain why?

Figure 11-35

Step by Step Answer:

Digital Systems Principles And Application

ISBN: 9780134220130

12th Edition

Authors: Ronald Tocci, Neal Widmer, Gregory Moss