Drag reduction is generally done by injecting the polymer into the center of the tube with the

Question:

Drag reduction is generally done by injecting the polymer into the center of the tube with the fluid. However, then one needs to wait for the polymer to move toward the wall. Injecting through the tube wall should be more efficient. In such circumstances the friction factor becomes a function of polymer concentration given by:

\[\frac{1}{\sqrt{f}}=(4.0+\delta) \log _{10} \operatorname{Re}_{d} \sqrt{f}-0.4-\delta \log _{10}[d W * \sqrt{2}]\]

with

\[R_{g} W^{*}=\Omega_{L} \quad \frac{\delta}{\sqrt{c}}=0.67\]

In this situation we will be using polyethylene-oxide (PEO) as the drag reducing agent. The target concentration in parts per million by weight, \(c=300 \mathrm{wppm}\). The molecular weight of the PEO is \(0.57 \times 10^{6}\) and its radius of gyration, \(R_{g}=81 \mathrm{~nm} . \Omega_{L}=7.1 \times 10^{-3}\). Use the Stokes-Einstein formulation to determine the diffusivity.

a. Based on the targeted, constant wall concentration, what is the friction factor for flow in this system and how does it compare to the friction factor in the absence of polymer? Assume a \(4 \mathrm{~cm}\) pipe diameter, a flow rate of \(1 \mathrm{~kg} / \mathrm{s}\), and a solution having the properties of water at \(25^{\circ} \mathrm{C}\).

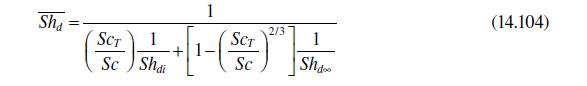

b. If the fluid enters a \(10 \mathrm{~km}\) pipe, \(4 \mathrm{~cm}\) in diameter with zero polymer content and at a flow rate of \(1 \mathrm{~kg} / \mathrm{s}\), what would be the average polymer concentration in the pipe at the exit? Assume the Churchill/Zajic expression for the Sherwood number; equation (14.104) is appropriate for determining the inside mass transfer coefficient.

Step by Step Answer: