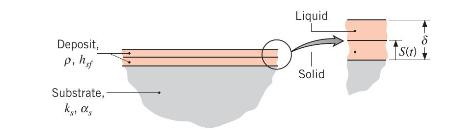

Special coatings are often formed by depositing thin layers of a molten material on a solid substrate.

Question:

Special coatings are often formed by depositing thin layers of a molten material on a solid substrate. Solidification begins at the substrate surface and proceeds until the thickness \(S\) of the solid layer becomes equal to the thickness \(\delta\) of the deposit.

(a) Consider conditions for which molten material at its fusion temperature \(T_{f}\) is deposited on a large substrate that is at an initial uniform temperature \(T_{i}\). With \(S=0\) at \(t=0\), develop an expression for estimating the time \(t_{d}\) required to completely solidify the deposit if it remains at \(T_{f}\) throughout the solidification process. Express your result in terms of the substrate thermal conductivity and thermal diffusivity \(\left(k_{s}, \alpha_{s}\right)\), the density and latent heat of fusion of the deposit \(\left(ho, h_{s f}\right)\), the deposit thickness \(\delta\), and the relevant temperatures \(\left(T_{f}, T_{i}\right)\).

(b) The plasma spray deposition process of Problem 5.21 is used to apply a thin \((\delta=2 \mathrm{~mm})\) alumina coating on a thick tungsten substrate. The substrate has a uniform initial temperature of \(T_{i}=\) \(300 \mathrm{~K}\), and its thermal conductivity and thermal diffusivity may be approximated as \(k_{s}=120 \mathrm{~W} / \mathrm{m} \cdot \mathrm{K}\) and \(\alpha_{s}=4.0 \times 10^{-5} \mathrm{~m}^{2} / \mathrm{s}\), respectively. The density and latent heat of fusion of the alumina are \(ho=3970 \mathrm{~kg} / \mathrm{m}^{3}\) and \(h_{s f}=3577 \mathrm{~kJ} / \mathrm{kg}\), respectively, and the alumina solidifies at its fusion temperature \(\left(T_{f}=2318 \mathrm{~K}\right)\). Assuming that the molten layer is instantaneously deposited on the substrate, estimate the time required for the deposit to solidify.

Data From Problem 5.21:-

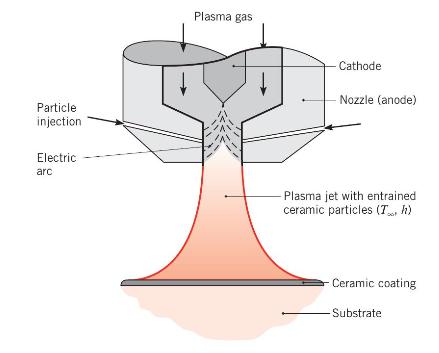

Plasma spray-coating processes are often used to provide surface protection for materials exposed to hostile environments, which induce degradation through factors such as wear, corrosion, or outright thermal failure. Ceramic coatings are commonly used for this purpose. By injecting ceramic powder through the nozzle (anode) of a plasma torch, the particles are entrained by the plasma jet, within which they are then accelerated and heated.

During their time-in-flight, the ceramic particles must be heated to their melting point and experience complete conversion to the liquid state. The coating is formed as the molten droplets impinge (splat) on the substrate material and experience rapid solidification. Consider conditions for which spherical alumina \(\left(\mathrm{Al}_{2} \mathrm{O}_{3}\right)\) particles of diameter \(D_{p}=50 \mu \mathrm{m}\), density \(ho_{p}=3970 \mathrm{~kg} / \mathrm{m}^{3}\), thermal conductivity \(k_{p}=10.5 \mathrm{~W} / \mathrm{m} \cdot \mathrm{K}\), and specific heat \(c_{p}=1560 \mathrm{~J} / \mathrm{kg} \cdot \mathrm{K}\) are injected into an arc plasma, which is at \(T_{\infty}=10,000 \mathrm{~K}\) and provides a coefficient of \(h=\) \(30,000 \mathrm{~W} / \mathrm{m}^{2} \cdot \mathrm{K}\) for convective heating of the particles. The melting point and latent heat of fusion of alumina are \(T_{\mathrm{mp}}=2318 \mathrm{~K}\) and \(h_{s f}=3577 \mathrm{~kJ} / \mathrm{kg}\), respectively.

(a) Neglecting radiation, obtain an expression for the time-in-flight, \(t_{i-f}\), required to heat a particle from its initial temperature \(T_{i}\) to its melting point \(T_{\mathrm{mp}}\), and, once at the melting point, for the particle to experience complete melting. Evaluate \(t_{i-f}\) for \(T_{i}=300 \mathrm{~K}\) and the prescribed heating conditions.

(b) Assuming alumina to have an emissivity of \(\varepsilon_{p}=0.4\) and the particles to exchange radiation with large surroundings at \(T_{\text {sur }}=300 \mathrm{~K}\), assess the validity of neglecting radiation.

Step by Step Answer:

Fundamentals Of Heat And Mass Transfer

ISBN: 9781119220442

8th Edition

Authors: Theodore L. Bergman, Adrienne S. Lavine