The Kaolene Co. Ltd has six different products all made from fabricated steel. Each product passes through

Question:

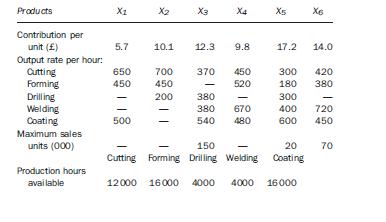

The Kaolene Co. Ltd has six different products all made from fabricated steel. Each product passes through a combination of five production operations: cutting, forming, drilling, welding and coating.

Steel is cut to the length required, formed into the appropriate shapes, drilled if necessary, welded together if the product is made up of more than one part, and then passed through the coating machine. Each operation is separate and independent, except for the cutting and forming operations, when, if needed, forming follows continuously after cutting. Some products do not require every production operation.

The output rates from each production operations, based on a standard measure for each product, are set out in the tableau below, along with the total hours of work available for each operation. The contribution per unit of each product is also given. It is estimated that three of the products have sales ceilings and these are also given below:

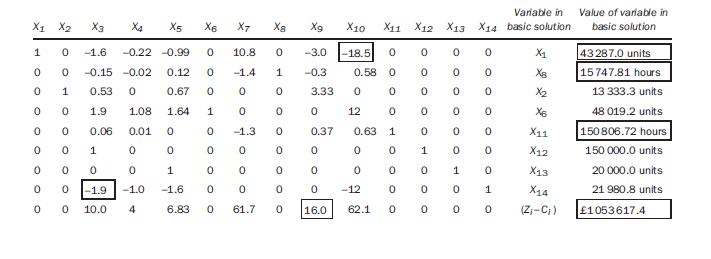

The production and sales for the year were found using a linear programming algorithm. The final tableau is given below.

Variables X7 to X11 are the slack variables relating to the production constraints, expressed in the order of production.

Variables X12 to X14 are the slack variables relating to the sales ceilings of X3, X5 and X6 respectively.

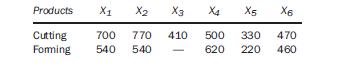

After analysis of the above results, the production manager believes that further mechanical work on the cutting and forming machines costing £200 can improve their hourly output rates as follows:

Requirements:

(a) Explain the meaning of the seven items ringed in the final tableau.

(b) Show the range of values within which the following variables or resources can change without changing the optimal mix indicated in the final tableau (i) c4: contribution of X4 (ii) b5: available coating time.

(c) Formulate the revised linear programming problem taking note of the revised output rates for cutting and forming.

(d) Determine whether the changes in the cutting and forming rates will increase profitability.

(e) Using the above information discuss the usefulness of linear programming to managers in solving this type of problem.

Step by Step Answer: