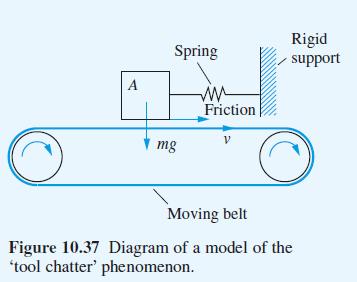

Figure 10.37 shows a system that serves as a simplified model of the phenomenon of tool chatter.

Question:

Figure 10.37 shows a system that serves as a simplified model of the phenomenon of ‘tool chatter’. The mass A rests on a moving belt and is connected to a rigid support by a spring. The coefficient of sliding friction between the belt and the mass is less than the coefficient of static friction. When the spring is uncompressed, the mass moves to the right with the belt. As it does so, the spring is compressed until the force exerted by the spring exceeds the maximum static frictional force available. The mass then starts to slide. The spring force slows the mass, brings it to rest, and then accelerates it back along the belt so that it moves leftwards. As it does so, the compression in the spring is reduced, the force of sliding friction slows the mass to rest, and then accelerates it so that its velocity is directed to the right. When its velocity matches that of the belt, sliding ceases and static friction takes over again.

Thus the mass undergoes a cyclic process of being pushed forwards by static friction until the spring is sufficiently compressed and then being flung backwards by the stored energy in the spring until the energy is dissipated. Analyse the model, determining such quantities as how the amplitude and frequency of motion of the mass depend on the coefficients and static friction and the other physical parameters.

Step by Step Answer: