Raul Suarez is the factory manager for Tallis Manufacturing, which manufactures metal propellers for small boats. The

Question:

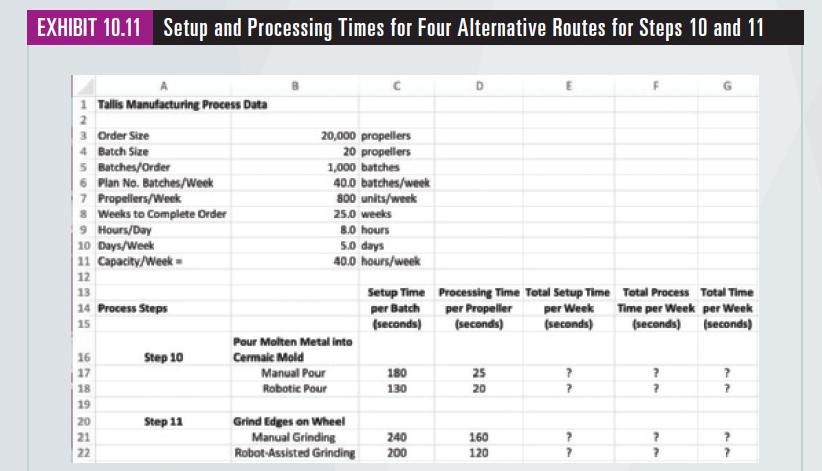

Raul Suarez is the factory manager for Tallis Manufacturing, which manufactures metal propellers for small boats. The factory uses hot plastic and metal work in the production process, so the factory is noisy, hot, and dangerous. The propeller production process currently operates five days a week for eight productive hours (not including lunch and breaks). It includes about 20 steps in a batch (job shop) type process. A batch consists of 20 propellers. The process begins when plastic pellets are melted and pressed in a large steel molding machine. The plastic propeller cast is dipped into hot wax, then it’s washed and dipped in a nonstick coating, and finally it’s dipped in sand. The propeller molds are heated in small batches in a pressurized autoclave oven and the wax and oily residues melt away, leaving a strong ceramic shell. They heat the molten metal in a separate oven.At process step 10, a worker uses a long steel claw to pick up and move the mold to a staging area where two employees pour the molten steel into the mold. The molten steel cools and they knock off the external ceramic mold leaving the metal propeller. The outer mold crumbles into pieces to the factory floor. All employees are wearing heat resistant clothing, face shields, and safety shoes. In step 11, the employees cut off extra metal and grind the propeller edges to make them smooth. Workers do the grinding because they can quickly see the burrs and blemishes, and where to and where not to grind. They hold the small propeller and grind it against a rotating finishing wheel. Once the worker thinks the propeller is finished, the propellers are batched and placed in a vat of vibrating metal chips to polish them. Next, lasers measure each propeller to see if it meets design specifications. If the propeller is within the specifications, it is polished and packaged for shipment. Raul has researched the benefits of automating some of this work using industrial robots. Similar applications of robots in other firms have been highly successful and reduced accidents and injuries, lowered manufacturing costs, and sped up the entire production process. He wants to evaluate the benefits of using robots to handle and dip hot molds and metal propellers into chemical baths, sand, and polishing chips in comparison to the current manual method. Raul built a spreadsheet for a new order of 20,000 propellers shown in Exhibit 10.11.

The time estimates in the exhibit also include employee rest and safety time. Steps 10 and 11 are the bottleneck steps (i.e., constraining resource), so only these are relevant in the analysis. All other steps in the propeller-making process are assumed to have plenty of safety capacity. Raul wants to compute the capacity required (total time in seconds) for this order of 20,000 propellers in steps 10 and 11 for both the current manual processes and the proposed automated processes using robots. In step 10, a robotic pouring machine would replace the worker doing the pouring manually. In step 11, a robot arm would pick up and hold the propeller while the machinist guides the grinding, and then the robot returns the finished propeller to in-process inventory. The machinist must program and adjust the robot often for grinding. Thus, there are four possible combinations of options:

1.Step 10—manual pour; Step 11—manual grinding

2.Step 10—manual pour; Step 11—robot-assisted grinding

3.Step 10—robotic pour; Step 11—manual grinding

4.Step 10—robotic pour; Step 11—robot-assisted grinding

Case Questions for Discussion

1.Compare the total time required to complete the order for 20,000 propellers for both the manual and automated processes in steps 10 and 11 by completing the spreadsheet in Exhibit10.11. What do you recommend that Raul should do?

2.What is the required capacity in hours per week for the order of 20,000 propellers for each of the four possible combinations of options for steps 10 and 11?

3.Based purely on capacity criteria (that is, ignore cost, quality, and safety criteria), what are your final short- and long-term recommendations?

Step by Step Answer:

Operations And Supply Chain Management

ISBN: 9780357901649

3rd Edition

Authors: David A. Collier; James Evans