After one year you are promoted to assistant manager and realize current inventory management practices are not

Question:

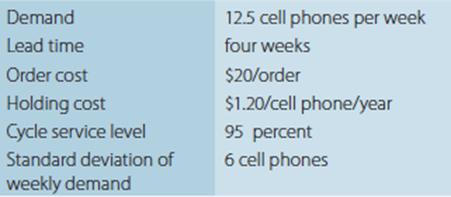

After one year you are promoted to assistant manager and realize current inventory management practices are not systematic with too much stock of some SKUs and too little of others. Your retail store operates 52 weeks per year and one SKU you stock is a high-end cell phone. The company’s current order quantity is 250 cell phones per order. You collect the following information about this cell phone and want to set up a fixed-order quantity (FQS) to impress higher-level managers and get promoted again!

Current on-hand inventory is 35 cell phones, with a scheduled receipt for 20 cell phones and no backorders.

a. What is the economic order quantity (EOQ)?

b. What is the reorder point with safety stock?

c. Based on the FQS information calculated previously, should an order be placed and if so, for how many cell phones?

d. What is the total annual cost savings using the EOQ you computed previously versus the current ordering policy of Q = 250 cell phones?

e. If you change to a fixed-period system (FPS) and all other information remains the same, what is the review period (T)?

f. What is the replenishment level (M) with safety stock for this FPS?

Step by Step Answer:

Operations And Supply Chain Management

ISBN: 9780357131695

2nd Edition

Authors: David A. Collier, James R. Evans