Mity-Lite (ML) is a manufacturer of folding and stackable chairs and folding tables for social events. The

Question:

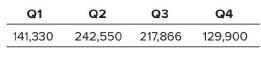

Mity-Lite (ML) is a manufacturer of folding and stackable chairs and folding tables for social events. The demand for ML's products is seasonal, peaking in spring and summer. Suppose it is December now, and the production manager needs to prepare the production plan for the next 12 months (for simplicity we use four quarters). Also for simplicity, we aggregate all products. The forecast during each of the next four quarters is:

ML currently employs 348 ''permanent" workers. The workers are paid $10 per hour and work 480 hours a quarter. The workers can make approximately 167 ,040 units per quarter during regular time (10 hours a day, four days a week). (Note: This works out to one hour per unit per worker.) They can also work up to 25 percent more as overtime (i.e., work 10 hours more on Fridays) and will be paid 1.5 times the regular wage rate. ML can hire up to 200 temporary workers for a second shift. The average hiring cost (searching, interviewing, and training) is estimated to be $480 per new employee. (Note: Hiring cost is charged to each unit produced during the first quarter of employment.) Temps are kept for one or two quarters.

For simplicity, we assume that the productivity of a new temp worker is the same as a permanent worker. Also, a temp worker's wage rate is $10 per hour. The inventory holding cost rate per quarter is 3 percent of unit cost, and the unit cost is $90. There are no products on hand now, and the desired seasonal inventory at the end of the year is zero. (In reality, ML keeps the equivalent of two weeks of demand as safety stock; we can assume that these are kept separately.) ML wishes to meet all demand, but shortage during any quarter (except the last) is allowed, in which case assume that the shortage is back ordered at the cost of $15 per unit per quarter.

a. Calculate all the relevant unit costs. Suppose ML uses permanent workers during regular time and nothing else. In the last quarter, ML will produce only what is needed and then will let workers go on vacation (i.e., they plan to produce 129,900 units). Determine the number of units short during each quarter.

b. Suppose ML hires temp workers to meet the shortages of part a. Determine when and how many temp workers should be used.

c. Using trade-off analysis, show why levelling (i.e., equalizing) the temp workers in Q2 and Q3 of the above solution is not cost-effective.

d. Using trade-off analysis, show why using permanent workers during overtime in part b's solution is not cost-effective.

Step by Step Answer:

Operations Management

ISBN: 9781259270154

6th Canadian Edition

Authors: William J Stevenson, Mehran Hojati, James Cao