A garment manufacturer is interested in using the data collected during value stream mapping to evaluate the

Question:

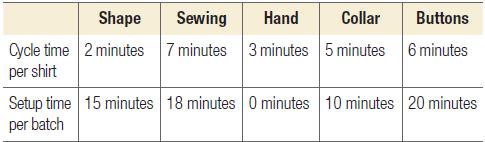

A garment manufacturer is interested in using the data collected during value stream mapping to evaluate the current state performance of the capacity of its manual assembly line process and would like to identify the ideal batch size for its operations. The productive capacity of the staff is 420 minutes per day. To manufacture a garment after design approval, clothes are cut into desired shape, followed by sewing of front and back, and then attachments of hand, collars, and buttons. The current operating characteristics of each processing step are found in the accompanying table. Note that each step can only process one part at a time and all steps must process the same sized batches.

a. Calculate the average processing time per unit and the capacity at each step assuming batch sizes of:

i. 20 shirts

ii. 30 shirts

iii. 35 shirts

iv. 40 shirts

b. Identify the bottleneck operation for each batch size.

c. What is the optimum batch size after which there will be no improvement in the line’s processing capacity?

Step by Step Answer:

Operations Management Processes And Supply Chains

ISBN: 9781292409863

13th Global Edition

Authors: Lee Krajewski, Naresh Malhotra, Larry Ritzman