1. Form groups. Read the case Bacon processing line. 2. Which principles and practices of Taylorist and...

Question:

1. Form groups. Read the case Bacon processing line.

2. Which principles and practices of Taylorist and Fordist forms of work organization can you identify in the current work arrangements?

3. Management consultants have reported that these arrangements are not very efficient. It has proved impossible to balance the line effectively so that staff at each workstation are fully occupied and each machine is fully utilized. How might this process and the jobs associated with it be more effectively designed to (a) maximize output and (b) benefit the employees? Imagine a factory in which sides of bacon (weighing about 20 kg) are cut into slices and vacuum-packed into pack sizes ranging from 500 grams to 3 kg. The small sizes are sold to supermarkets for domestic purchases and the larger packs are sold directly to hotel and catering outlets for commercial use. The bacon curing process leaves the meat wet and slippery and it has to be kept at a low temperature in order to preserve it. In practice before a side of bacon is sliced by the machine it has to be frozen in order to make it cut easily and retain its shape during the packing process. This makes the working conditions cold, damp, and unpleasant to work in. The overall process involves the slicing and packaging of bacon, and includes the following jobs and activities:

• A frozen side of bacon needs to be fed into a machine which then cuts it into slices.

• The slices need to be separated and stacked in pack quantity on a moving conveyor belt.

• The individual stacks of bacon need to be placed into a packing machine.

• The packing machine needs to be set up for the type of pack to be produced and needs to be, monitored during the packing process.

• The packed bacon needs to be weighed, priced, and labelled.

• The packs need to be checked for presentation, label accuracy, and quality.

• Individual packs of bacon need to be put into cardboard boxes ready for cold storage and despatch to customers.

• The cardboard boxes need to be labelled with the contents and customer details.

• The cardboard boxes need to be stacked onto wooden pallets and moved to the cold store for despatch to customers.

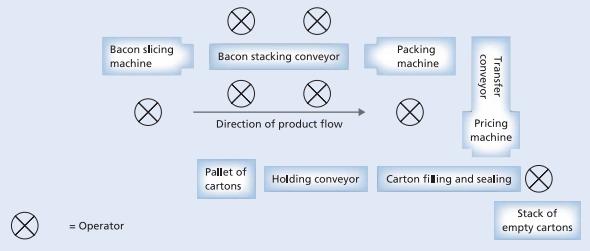

The layout diagram represents the machine layout and people workstations identified using a work-study-based job simplification exercise. The simplified tasks in this job involved:

Slicing One person is responsible for obtaining the bacon, setting and cleaning the slicing machine, and pacing the slicing processes to keep the other workstations fully utilized. This operator could wear gloves to keep their hands warm when picking up the frozen sides of bacon and feeding them into the machine.

Stacking Four people working on either side of a conveyor belt splitting the cut bacon into stacks of the right quantity as it passes them by. The conveyor belt speed and rate of slicing sets the pace the work for these operators.

This operation was rather like separating out a specific number of pages from a sheaf of papers. It required dexterity and the ability to use the fingers and fingernails to separate out the correct number of frozen slices of bacon. It was difficult to do this wearing gloves and so the work was very cold and not the most pleasant of tasks.

Packing One person responsible for setting the machine, placing individual stacks of bacon into it and generally ensuring a smooth operation. They would also monitor the quality of the packed product.

Pricing and boxing One person is responsible for setting the automatic weighing and pricing machine, boxing the packs of bacon, sealing and labelling the boxes, and stacking the cartons on a pallet ready for transport to the cold store. This person would also monitor pack quality, rejecting faulty packs and stopping the line to reset the machine if necessary.

Transport Someone else would remove loaded pallets and bring empty ones as part of a similar job for other packing stations.

In addition to these direct production activities there would be a need to keep records of output and quality. Also the group would need to ensure that the whole process worked smoothly with individuals working as a team. Using work measurement techniques the number of operators (and tasks) needed at each workstation illustrated in the diagram would be determined in order to produce the highest possible levels of output. In this case it is suggested in the diagram that a balanced line contains eight people (including one shared with other lines). However, it could be that the slicer operator is only working for 50 per cent of the time. Under these circumstances it would be common to recalculate the line speeds or design the jobs to keep worker utilization as high as possible.

Step by Step Answer:

Organizational Behavior

ISBN: 978-0273774815

8th Edition

Authors: Andrzej A. Huczynski, David A. Buchanan