Question: EZ-Windows, Inc., manufactures replacement windows for the home remodeling business. In January, the company produced 14,000 windows and ended the month with 9,500 windows

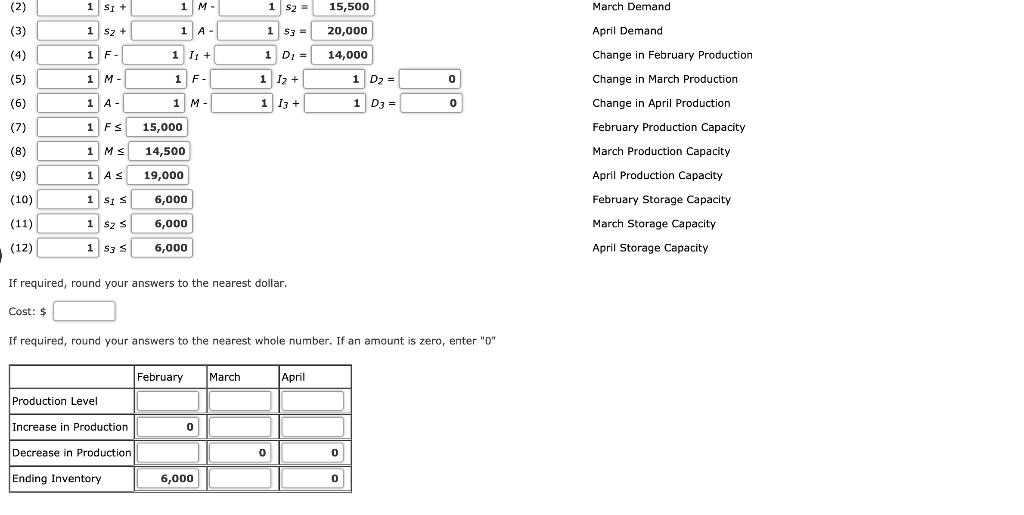

EZ-Windows, Inc., manufactures replacement windows for the home remodeling business. In January, the company produced 14,000 windows and ended the month with 9,500 windows in inventory. EZ-Windows' management team would like to develop production schedule for the next three months. A smooth production schedule is obviously desirable because it maintains the current workforce and provides a similar month-to-month operation. However, given the sales forecasts, the production capacities, and the storage capabilities as shown, the management team does not think a smooth production schedule with the same production quantity each month is possible. February March April Sales forecast 14,000 15,500 20,000 Production capacity 15,000 14,500 19,000 Storage capacity 6,000 6,000 6,000 The company's cost accounting department estimates that increasing production by one window from one month to the next will increase total costs by $1.00 for each unit increase in the production level. In addition, decreasing production by one unit from one month to the next will increase total costs by $0.65 for each unit decrease in the production level. Ignoring production and inventory carrying costs, formulate and solve a linear programming model that will minimize the cost of changing production levels while still satisfying the monthly sales forecasts. If required, round your answers to two decimal places. If an amount zero, enter "0". Let: F = number of windows manufactured in February M = number of windows manufactured in March A = number of windows manufactured in April Im = increase in production level necessary during month m Dm = decrease in production level necessary during month m Sm = ending inventory in month m (2) 1 SI + 1 M - 1 s2 = 15,500 March Demand (3) 1 sz + 1|A - 1 S3 = 20,000 April Demand (4) 1F- 1 It + 1 D = 14,000 Change in February Production (5) 1 M - 1F- 1 Iz + 1 Dz = Change in March Production (6) 1 A- 1 M - 1 13 + 1 D3 = Change in April Production (7) 1 Fs 15,000 February Production Capacity (8) 1MS 14,500 March Production Capacity (9) 1 AS 19,000 April Production Capacity (10) 1 Si S 6,000 February Storage Capacity (11) 1 s2 3 6,000 March Storage Capacity (12) 1 s3 S 6,000 April Storage Capacity If required, round your answers to the nearest dollar. Cost: $ If required, round your answers to the nearest whole number. If an amount is zero, enter "0" February March April Production Level Increase in Production Decrease in Production Ending Inventory 6,000

Step by Step Solution

3.38 Rating (154 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts