Based on the problem statement of Example 14.20, design a four-stage diafiltration section to take the 55

Question:

Based on the problem statement of Example 14.20, design a four-stage diafiltration section to take the 55 wt% concentrate from Section 1 and achieve the desired 85 wt% concentrate, thus eliminating Section 3.

Example 14.20

A cheese plant produces a byproduct stream of 1,000,000 lb/day of whey, to be further processed to obtain a dry powder containing 85 wt% combined TP (true protein) and NPN (nonprotein nitrogen compounds). The process includes three sections:

(1) Four stages of continuous bleed-and-feed ultrafiltration to reach 55 wt% (dry basis), followed by

(2) Four stages of continuous diafiltration to reach 75 wt% (dry basis), followed by

(3) One stage of batch diafiltration to reach the final 85 wt% (dry basis), with a batch-time limit of 4 hours. Diafiltration must be used above 55 wt% because the retentate from UF becomes too viscous. Each section will use PM 10 ultrafiltration hollow-fiber membrane cartridges from Koch Membrane Systems, which are 3 inches in diameter by 40 inches long, with 26.5 ft2 of membrane area, at a cost of $200.00 each. For each cartridge, the recirculation (recycle) rate is 23 gpm. The number of cartridges is to be the same in each stage for Sections 1 and 2. The inlet pressure to each is 30 psig, with a crossflow pressure drop of 15 psi and a permeate pressure of 5 psig. For these conditions, the membrane flux has been measured for the whey and correlated as a function of the concentration factor, CF, by:

![]()

where CF, for any stage n, is defined by reference to the fresh feed to Section 1, as

![]()

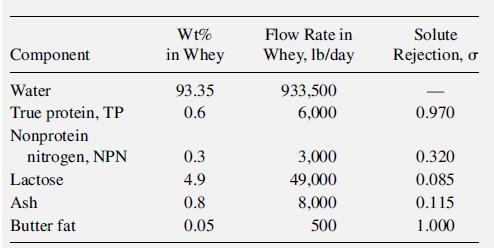

Whey composition and membrane–solute rejections, σ, are:

Based on s values, the membrane increases the concentration of TP while selectively removing the low-MW solutes of lactose and ash. Whey and all retentate and permeate streams have a density of 8.5 lb/gal. The continuous sections of the process will operate 20 hr/day, leaving 4 hr/day to remove accumulated membrane foulants and sterilize equipment. For each section, calculate:

(1) Component material balances in lb/day of operation, including dilution water for diafiltration;

(2) Percent recovery from whey of TP and NPN in the intermediate and final 85 wt% concentrate; and

(3) Number of membrane cartridges. Also, for Section 1, make calculations for a single continuous stage, compare results to those for four stages, and discuss advantages and disadvantages of four stages versus one stage.

Step by Step Answer:

Separation Process Principles Chemical And Biochemical Principles

ISBN: 9780470481837

3rd Edition

Authors: By J. D. Seader, Ernest J. Henley, D. Keith Roper