In the manufacture of paper, large amounts of electricity, process steam, and hot water are required. While

Question:

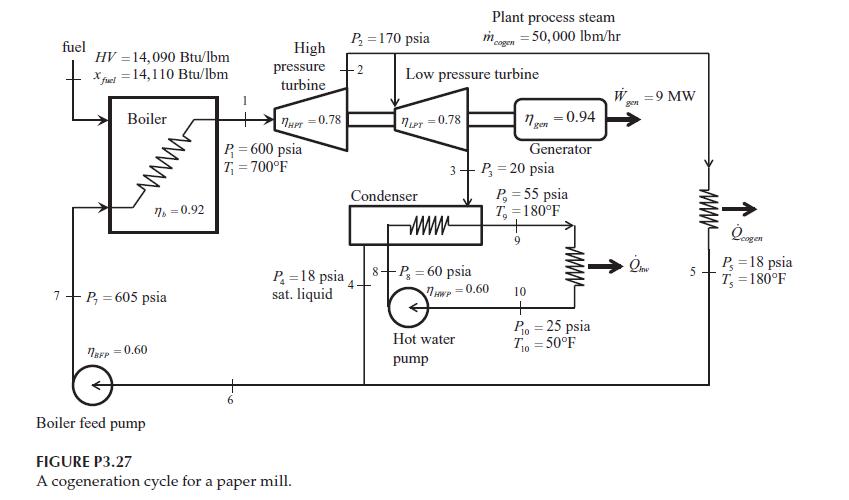

In the manufacture of paper, large amounts of electricity, process steam, and hot water are required. While these three needs could be met by individual thermal energy systems, it is prudent to develop a single system that can provide all three needs with one fuel source. A thermodynamic cycle that accomplishes this is called a cogeneration cycle. Consider a cogeneration cycle in a paper mill as shown in Figure P3.27. A fuel is combusted in the boiler and steam is produced at 600 psia, 700°F. This steam runs through a high-pressure turbine with an isentropic efficiency of 78% and exhausts to a pressure of 170 psia. At the high-pressure turbine exhaust, 50,000 lbm/hr of steam are extracted for process heating (labeled cogen in Figure P3.27). The process steam makes its way through several heating processes in the mill and condenses to 18 psia, 180°F. This flow is then combined with saturated liquid water leaving the condenser before being pumped back into the boiler.

The balance of the steam from the high-pressure turbine exhaust passes through the low-pressure turbine and exhausts at a pressure of 20 psia. The isentropic efficiency of the low-pressure turbine is 78%. The turbines deliver power to an electrical generator that has an efficiency of 94%. The generator delivers 9 MW of power to the mill. This power is used for all mill operations including the operation of the pumps in the cogeneration cycle.

The low-pressure turbine exhaust is purposely kept high so the plant hot water needs can be satisfied. The plant hot water enters the condenser at 60 psia and exits at 55 psia, 180°F. The hot water returns from the mill at 25 psia, 50°F before being pumped to 60 psia through the hot water pump that has an isentropic efficiency of 72%. After the saturated liquid from the condenser and hot water from the process heating combine, they pass through the boiler feed pump with an isentropic efficiency of 60%. The boiler feed pump isentropic efficiency is 60% and the water exits at a pressure of 605 psia. The fuel used in the boiler is natural gas with heating value (HV) of 14,090 Btu/lbm and an exergy content of 14,110 Btu/lbm. The boiler has an efficiency of 92%.

Determine the,

a. Mass flow rate of the steam passing through the high-pressure turbine (lbm/hr).

b. Mass flow rate of steam passing through the low-pressure turbine (lbm/hr)

c. Mass flow rate of the hot water delivered to the plant (lbm/hr)

d. Required mass flow rate of the fuel (lbm/hr)

e. Heat transfer rate that is provided to the mill by the process steam (Btu/hr)

f. Heat transfer rate that is provided to the mill by the hot water (Btu/h)

g. Thermal efficiency of the cycle based on (energy sought)/(energy that costs)

h. Exergy transfer rate from the exergy resource input to the cycle (Btu/hr)

i. Exergy transfer rate representing the exergy task of the cycle (Btu/hr). When considering the exergy task associated with the heat transfers from the cogeneration cycle, it will be difficult to determine the exergy transfer rate associated with the heat transfers because the boundary temperatures are unknown.

Therefore, when considering the exergy task associated with the heat transfers, assume the task to be the decrease in flow exergy of the water as it passes through each process.

j. Exergetic efficiency of the cycle based on the (exergy task)/(exergy resource)

You should discover that the thermal efficiency of this cycle is very high, but the exergetic efficiency is very low. What you have discovered is that this cogeneration cycle is very good at utilizing energy but is not doing so well with the exergy it has been given by the fuel. To decipher why this is happening, determine the following, k. The exergy destruction rate in the boiler, high pressure turbine, low pressure turbine, condenser, boiler feed pump, and hot water pump (Btu/hr)

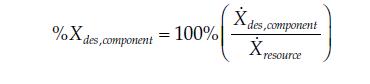

l. Now, convert the exergy destruction answers in parts (k) to a percent of the exergy resource input rate to the cycle,

m. The result of this problem demonstrates the energy/exergy conundrum. Based on the results of your analysis, you should have discovered that the boiler exergy destruction rate is responsible for the low exergetic efficiency of the system. What do you think is causing this large exergy destruction rate? Is there anything that the engineer can do to reduce the exergy destruction in the boiler and increase the exergetic efficiency of the cycle? Is it possible to make the exergetic efficiency better and resolve the energy/exergy conundrum?

Step by Step Answer:

Thermal Energy Systems Design And Analysis

ISBN: 9781138735897

2nd Edition

Authors: Steven G. Penoncello