Tata Motors Private Limited is a leading manufacturer of trucks in India and Indias largest automobile company.

Question:

Tata Motors Private Limited is a leading manufacturer of trucks in India and India’s largest automobile company. It is the second-largest manufacturer of passenger vehicles in the world. The company is the world’s fifth-largest medium and heavy commercial vehicles manufacturer and the world’s second-largest medium and heavy bus manufacturer.

Tata Indica

Ratan Tata, the chairman of Tata Motors, had always dreamed of building the country’s first indigenous small car. In 1995, the company announced that it planned to build the Tata Indica, a car as spacious as the Ambassador, priced close to the Maruti 800 and shaped like the Zen. Tata Motors had to face many challenges in the process of designing and building the Indica.

Outsourcing

Tata Motors had to take its primary make or buy decisions for the key inputs such as design, engine and transmission. Outsourcing was one of the most difficult aspects of producing the Indica.

The company did not have the expertise either to design a car or to build an engine for it.

It had to create a supplier base from scratch. The company decided to shop globally for the best deals and use its own expertise to make whatever modifications were needed.

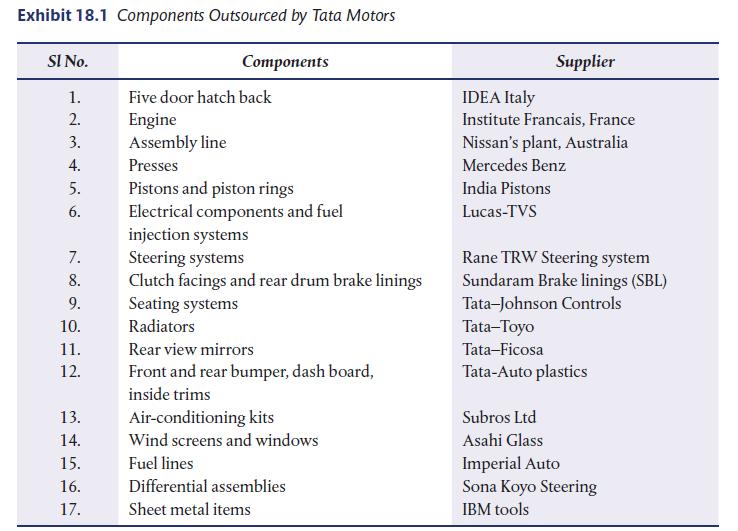

Exhibit 18.1 provides a list of components outsourced for developing the Indica.

Supplier Quality Audit

After making the make or buy decisions, the next step was to identify the suppliers. Most of the parts and components were sourced locally. Only about two per cent of the component value was secured from other global players. Localization of the components was the most important challenge for the company. The Indica was totally indigenous.

Tata Motors undertook supplier audits to select and monitor suppliers during the development of the Indica. Supplier audit is an integral part of the decision process for supplier selection. It enables guarantees regarding design, manufacturing, system, product, raw material and services. It also enables answering to regulatory requirements which impose these audits. A supplier quality audit team was formed with a view to ensuring acceptable supplier quality, which became very critical. The yardstick employed by the company for selecting suppliers was the ability to supply components at the negotiated quality, cost and quantities. The selection of supplier by the team involved following steps:

• An initial assessment team from Tata Motors evaluated the supplier

• Self-evaluation of the supplier based on the format provided by the company

• Quality system survey design validation

• Manufacturing validation

• Product Part Approval Process (PPAP) for certifying the product quality

Tata Motors also set up Supplier Quality Improvement Teams to improve the vendors’ systems to ensure that they produced defect-free parts. It applied a thirteen-step quality improvement programme covering supplier self-evaluation, thorough design-validation and audit of supplier quality. Another key to the company’s successful vendor-base was a modern system of process management. Tata Motor’s target-costing was broken up into vendor-wise cost targets, and the suppliers had to carry out their own value-engineering exercises to lower cost and improve quality.

Question For Discussion

1. What were the challenges faced by TATA Motors while selecting its suppliers for Indica?

2. What were the reasons for setting up a supplier quality team at TATA motors?

3. What was the approach followed by the supplier quality audit team?

4. What is the difference between supplier quality audit and third party quality audit?

Step by Step Answer: