The Robotron-Elotherm company is known for its expertise in power electronics for welding, induction bonding, and process

Question:

Actually, the machines were shipped to a Michigan plant of Sanyo Manufacturing (a Japanese firm) that GM was using as a door builder. Sanyo Manufacturing was unhappy with the quality of the machines sent by Robotron. Robotron president Leonard Brzozowski went to the Sanyo plant to investigate the situation in person and learned that their Japanese had a much higher quality standard than the usual American customers.

Tolerances were much smaller and inspection was more demanding. Brzozowski said that he realized for the first time that the philosophy, engineering, management, and shop practices of Robotron did not qualify the company for world competition. Brzozowski said that this was the most embarrassing time of his professional career. What should Robotron do about this situation?

Brzozowski began by sending a group of hourly employees to the Sanyo plant. There they met the customer and heard firsthand the many complaints about their product. The workers could see the difference in quality between their machines and those of Sanyo. The plant visit was extremely effective. On the way home; the Robotron workers started discussing what they could do to improve quality.

The company took several steps to begin the process of quality improvement. It established new inspection procedures, bought more accurate inspection tools, changed internal control procedures, and developed baselines against which to measure progress. Teams were organized and sent out to customers six months after a purchase to determine customer satisfaction. A hotline was established for customers to call to report product dissatisfaction.

For one month, engineers assembled machinery in the shop under the direction of hourly employees. This exercise gave the engineers a new awareness of the importance of accurate, clear drawings; designing smaller, lighter-weight details; and minimizing the number of machined surfaces.

Robotron€™s effort paid off handsomely. Claims under warranty dropped 40% in three years, during which time orders rose at a compound annual rate of 13.5%. The company cut costs and streamlined procedures and processes. Sales increased and new markets opened. In 1997, Robotron received ISO-9001 certification. Early in 1998, Robotron merged with ELOTHERM, a European company; so that Robotron could more easily enjoy a presence in the European market and at the same time provide ELOTHERM opportunities in North America. Robotron€™s bonding business expanded into induction heating systems, heat treating, tube welding, and electrical discharge machines. The company maintains a quality system that takes corrective action in response to customer complaints, employee suggestions, or supplier defects.

Discussion

1. As a part of quality improvement, it is highly likely that Robotron analyzed its manufacturing processes. Suppose that as Robotron improved quality, the company wanted to examine other processes including the flow of work orders from the time they are received until they are filled.

Use the following verbal sketch of some of the activities that might take place in such a flow as a start, and add some of your own ideas as you draw a flowchart for the process of work orders.

Work order flow: Received at mailroom. Sent to order processing office. Examined by order-processing clerk who decides whether the item is a standard item or a custom item. If it is a standard item, the order is sent to the warehouse. If the item is available, the item is shipped and the order is sent to the billing department. If the item is not available, the order is sent to the plant where it is received by a manufacturing clerk. The clerk checks to determine whether such an item is being manufactured. If so, the order is sent to the end of the assembly line where it will be tagged with one such item. If not, the order is sent to the beginning of the assembly line and flows along the assembly line with the item as it is being made. In either case, when the part comes off the assembly line, the order is attached to the item and sent to shipping. The shipping clerk then ships the item and sends the order to billing. If the ordered item is a customized part, the order is sent straight from the order-processing clerk to manufacturing where it follows the same procedures as already described for standard items that have not been manufactured yet.

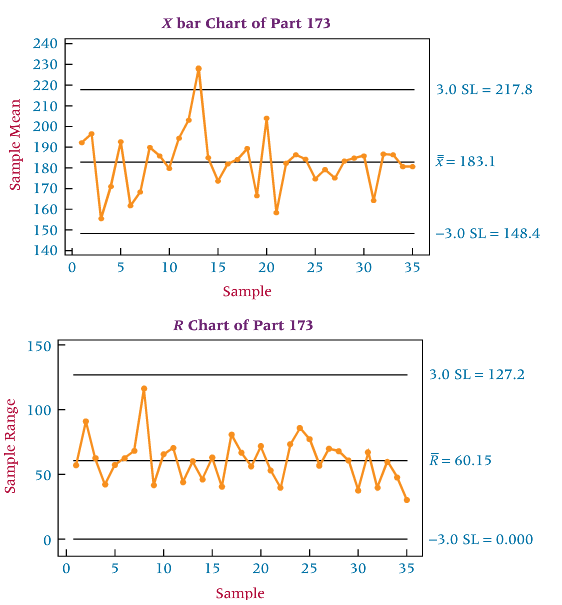

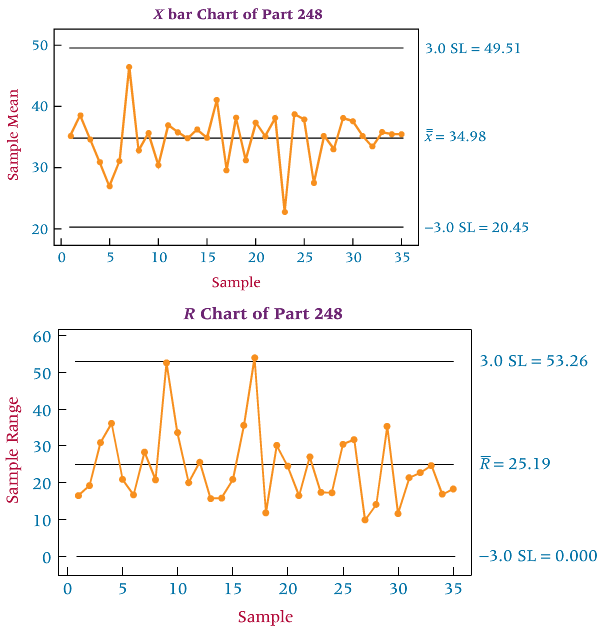

2. Virtually all quality manufacturers use some type of control chart to monitor performance. Suppose the Minitab control charts shown here are for two different parts produced by Robotron during a particular period. Part 173 is specified to weigh 183 grams. Part 248 contains an opening that is specified to be 35 millimeters in diameter.

Study these charts and report to Robotron what you found. Is there any reason for concern? Is everything in control?

3. Suppose Robotron also keeps p charts on non0conformance.The Minitab chart shown here represents the proportion of nonconforming items for a given part over 100 samples. Study the chart and write a brief report to Robotron about what you learned from the chart. Think about overall performance, out-of-control samples, samples that have outstanding performance and any general trends that you see.

Step by Step Answer:

Business Statistics For Contemporary Decision Making

ISBN: 978-1118749647

8th edition

Authors: Black Ken