You are the operations manager for a manufacturing plant that produces pudding food products. One of your

Question:

You are the operations manager for a manufacturing plant that produces pudding food products. One of your important responsibilities is to prepare an aggregate plan for the plant. This plan is an important input into the annual budget process. The plan provides information on production rates, manufacturing labor requirements, and projected finished goods inventory levels for the next year. You make those little boxes of pudding mix on packaging lines in your plant. A packaging line has a number of machines that are linked by conveyors. At the start of the line the pudding is mixed; it is then placed in small packets. These packets are inserted into the small pudding boxes, which are collected and placed in cases that hold 48 boxes of pudding. Finally, 160 cases are collected and put on a pallet. The pallets are staged in a shipping area from which they are sent to four distribution centers. Over the years, the technology of the packaging lines has improved so that all the different flavors can be made in relatively small batches with no setup time to switch between flavors. The plant has 15 of these lines, but currently only 10 are being used. Six employees are required to run each line.

Technical and Economic Information

Currently the plant is running 10 lines with no overtime. Each line requires six people to run. For planning purposes, the lines are run for 7.5 hours each normal shift. Employees, though, are paid for 8 hours’ work. It is possible to run up to 2 hours of overtime each day, but it must be scheduled for a week at a time, and all the lines must run overtime when it is scheduled. Workers are paid $ 20.00/ hour during a regular shift and $ 30.00/ hour on over-time. The standard production rate for each line is 450 cases/ hour.

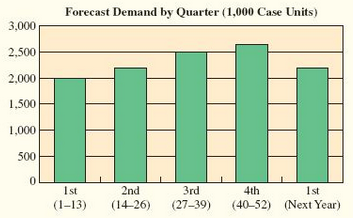

The marketing forecast for demand is as follows: Q1— 2,000; Q2— 2,200; Q3— 2,500; Q4— 2,650; and Q1 ( next year)— 2,200. These numbers are in 1,000- case units. Each number represents a 13- week forecast.

Management has instructed manufacturing to maintain a two- week supply of pudding inventory in the warehouses. The two- week supply should be based on future expected sales. The following are ending inventory target levels for each quarter: Q1— 338; Q2— 385; Q3— 408; Q4— 338.

Inventory carrying cost is estimated by accounting to be $ 1.00 per case per year. This means that if a case of pudding is held in inventory for an entire year, the cost to just carry that case in inventory is $ 1.00. If a case is carried for only one week, the cost is $ 1.00/ 52, or $. 01923. The cost is proportional to the time carried in inventory. There are 200,000 cases in inventory at the be-ginning of Q1 (this is 200 cases in the 1,000- case units that the forecast is given in).

If a stock out occurs, the item is backordered and shipped at a later date. The cost when a backorder occurs is $ 2.40 per case due to the loss of goodwill and the high cost of emergency shipping.

The human resource group estimates that it costs $ 5,000 to hire and train a new production employee. It costs $ 3,000 to lay off a production worker. 7 Make the following assumptions:

• Inventory costs are based on inventory in excess of safety stock.

• Backorder costs are incurred on negative deviation from planned safety stock, even though planned inventory may be positive.

• Overtime must be used over an entire quarter and should be based on hours per day over that time.

Questions

1 Prepare an aggregate plan for the coming year, assuming that the sales forecast is perfect. Use the spreadsheet “Bradford Manufacturing.” In the spreadsheet an area has been designated for your aggregate plan solution. Supply the number of packaging lines to run and the number of overtime hours for each quarter. You will need to set up the cost calculations in the spreadsheet. You may want to try using the Excel Solver to find a solution. Remember that your final solution needs an integer number of lines and an integer number of overtime hours for each quarter. (Solutions that require 8.9134 lines and 1.256 hours of overtime are not feasible.)

2 Review your solution carefully and be prepared to defend it. Bring a printout of your solution to class.

Goodwill is an important concept and terminology in accounting which means good reputation. The word goodwill is used at various places in accounting but it is recognized only at the time of a business combination. There are generally two types of... Ending Inventory

The ending inventory is the amount of inventory that a business is required to present on its balance sheet. It can be calculated using the ending inventory formula Ending Inventory Formula =... Distribution

The word "distribution" has several meanings in the financial world, most of them pertaining to the payment of assets from a fund, account, or individual security to an investor or beneficiary. Retirement account distributions are among the most...

Step by Step Answer:

Operations and Supply Chain Management

ISBN: 978-0078024023

14th edition

Authors: F. Robert Jacobs, Richard Chase