In February 19_8, Randy White, president of Arriscraft Corporation (Arriscraft), had just received two requests for a

Question:

Company Background

Arriscraft was established in Cambridge, Ontario in 1949 by E. B. Ratcliffe, a chemical engineer, to produce precast stones. In 1956, he developed a unique worldwide process that compressed sand into stone without the use of cement. The result was a stone that was more durable than the normal clay bricks or other masonry products and that could be formed into a variety of shapes, sizes, colours, and textures.

In 1962, Arriscraft added a second product line that involved the cutting of limestone blocks from a quarry near Wiarton, Ontario and the production of marble hearth slabs and windowsills in Cambridge. In 1980, additional marble products, of paving stones and building stones, were added to the line. These marble products are sold under the trade name Adair Marble.

As of 19_8, the company was the only producer of the manufactured stones in the world and was Canada's largest producer of marble products, with only one smaller competitor located in Winnipeg, Manitoba. Recently Arriscraft had been successful in obtaining some significant contracts that included supplying the marble stone for the Canadian Chancery in Washington, the Ontario Court House and Registry Office in Ottawa, and the reconstruction of the Rideau Canal locks. With these and other contracts, Arriscraft had established a reputation among architects and contractors as a leading producer of unique and top-quality stone products.

White had been with the company for nine years, after graduating from Queen's University with a degree in commerce and obtaining his Chartered Accountant designation. During his nine years, White held the positions of controller, executive vice-president, and president. With this experience, he was fully aware of both the financial and the technical implications of the various alternatives that he faced. In particular, he was acutely aware that the variability of the yields and product mix significantly complicated any analyses of product line profitability.

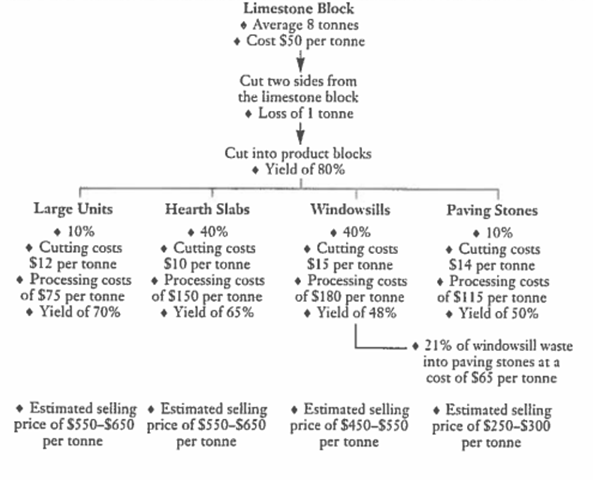

Production Process As the decisions facing White concerned marble products, only the production process related to these products will be described. Exhibit A7-1 illustrates the following description of this process.

First, limestone blocks are drilled and cut from a quarry. The top surface of the quarry is the side of the block, the dimensions are 30 inches by 84 inches. The depth of the block will vary depending upon the natural bed depth of the quarry, but lengths van' from three to ten feet. The net result are limestone blocks that vary in size from four to twelve tonnes, with an average size being approximately eight tonnes. These limestone blocks are then trucked to Arriscraft's plant. The total direct cost of the limestone blocks is approximately $50 per tonne, which includes the removal and transportation costs.

At the plant, each limestone block is positioned in front of a saw, which first cuts off two sides. These cuts will remove approximately one tonne of waste from an average eight-tonne block, leaving seven tonnes. Next, the saw operator must make a series of critical judgement calls as he or she cuts the limestone block into slices called product blocks. The saw operator must examine the face of the stone for cracks, pits, or other faults. If any are found, a cut approximately eight inches wide will be made and the product block will be further processed into paving stones. If the limestone block is reasonably clear of faults, then a six-inch cut will be made and the product block will be produced into windowsills. If the stone is of highest quality, then cuts varying from 6 to 30 inches will be made to produce specialized products and hearth slabs. A fourth product line is referred to as larger units, where the quality may be low and these sections would otherwise be used for paving stones. However, if a wider cut is made, the stone can be used in place of some top-quality large pieces for some specific applications. The skill of the saw operator is extremely important, as a limestone block will normally produce €¢ many grades of products, and thus a judgment call is required after each cut is made. The cutting of the limestone block into product blocks results in an 80% yield of the seven tonnes, and the cutting costs per tonne of product block vary for each of the four product lines as follows:

Paving stones $14 per tonne

Window sills 15 per tonne

Hearth slabs 10 per tonne

Large units 12 per tonne

While a variance of 10 to 15% exists, it is expected that 10% of the product block tonnage will be in paving stones, 40% in windowsills, 40% in hearth slabs, and 10% in large units.

The processing of the product blocks into their designated final products first involves some additional sawing and splitting. Then, depending upon the quality of the final product, the stones are honed (smoothed) to produce the marble product. The extent of the processing varies by product line and the ultimate yield will also vary by product line. The paving stones have a 50% yield and the processing costs total $115 per tonne of finished product. The windowsills have a yield of 48% with a processing cost of $180 per tonne of finished product. The waste from the win-dowsills can be used for paving stones, and after a further processing cost of 565 per tonne of finished product, a yield of 21% of the waste is obtained. The hearth slabs are processed for a cost of $150 per tonne of finished product, which is a 65% yield of the product blocks. The large units result in a yield of 70% for a processing cost of $75 per finished tonne.

The above description is the typical production process; however, it is possible to produce paving stones and windowsills from higher-grade material. While the cutting and processing costs for the paving stones and windowsills would remain the same, the yields would increase as follows. Windowsills may be cut from the mater-ial that would normally be used for hearth slabs and large units and the yields would increase by 10 percentage points to 75 and 80% respectively. Similarly, paving stones may be cut from windowsill, hearth slab, and large-unit materials with a 15-percentage-point increase in yields to 63%, 80%, and 85% respectively. In addition, the cutting of paving stones from windowsill waste would increase to 31%. White was, however, concerned that this alternative production process would not yield satisfactory profit margins.

Situation Summary

White had been faced many times with similar situations like those before him now. If 2,000 tonnes of paving stones are produced by means of the normal production process, more than the required quantities of windowsills must also be produced. Furthermore, product blocks that will eventually be produced into hearth slabs, and large units must also be cut even though they are not currently required. However, if the limestone blocks were cut into only paving scones, only windowsills, or both paving stones and windowsills, the higher-quality material would be used where lower-quality material would meet the customer requirements. The market for these marble products was somewhat unpredictable, as the orders tended to be large and depended essentially upon the preferences of an architect or contractor. While came from less expensive alternative building products. For example the paving stones will cost the city $4.29 a square foot, whereas interlocking brick (an alternative cement-based product) would cost $1 to $2 a square foot. The issue is essentially how much more the market is willing to pay for a marble product than a more common alternative.

Given the common costs of the limestone block and the cutting. White again wondered whether a price of $300 per tonne of paving stones and $500 per tonne of windowsills would generate sufficient profits. As a rule of thumb, the company has historically attempted to attain a markup of 100% on the direct product costs. Typically, a markup of less than 70% was viewed as unprofitable. However, in a situation such as this, the measurement of the direct costs by product line is not straightforward. Furthermore, the unsold product, both finished and unfinished, had always presented a problem when costing the inventory for Arriscraft€™s annual financial report. Depending upon the approach adopted, the costing of the inventory could have a material effect on the net income.

Required

As Randy White, would you bid on both of the orders and, if so, at what price? Explain your reasoning.

CorporationA Corporation is a legal form of business that is separate from its owner. In other words, a corporation is a business or organization formed by a group of people, and its right and liabilities separate from those of the individuals involved. It may...

Step by Step Answer:

Management Accounting

ISBN: 978-0132570848

6th Canadian edition

Authors: Charles T. Horngren, Gary L. Sundem, William O. Stratton, Phillip Beaulieu