Landry Associates produces a broad range of components for stereos and similar electronic products. It has been

Question:

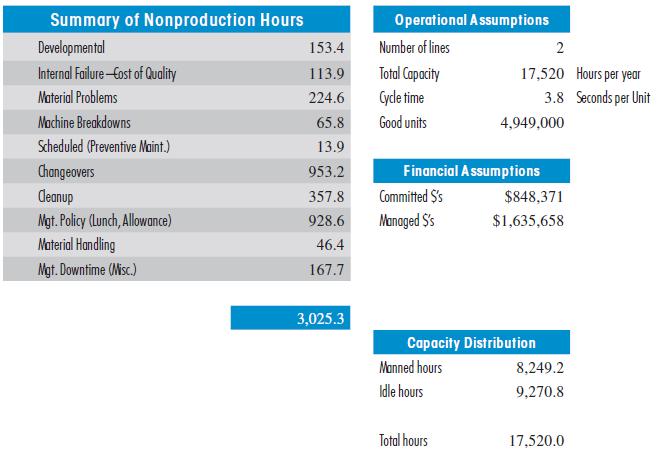

Landry Associates produces a broad range of components for stereos and similar electronic products. It has been having problems with profitability over the past few years. It runs a number of machines that make most of the components, but the machines sit idle a good percentage of the time. Since they are fairly expensive machines, Bruce Landry knows that this is the heart of his problem, but even when the lines are staffed, it seems like the factory is down more often than it is working.

Landry Associates began as a small machine shop back in the 1970s. It has always believed in treating its workforce well, so it provides employees with paid breaks and lunches. The company loses 816 hours a year for holidays and vacations, which is part of the total idle time. Management tries to get the most out of its machines, however, so it changes them over often to run a new type of component. The orders themselves can be fairly small, ranging anywhere from 5,000 to 100,000 units of one component. Each time a new order is run, the machines have to be set up. In addition, they often run into material problems as the parts that go into making a component can be very small and hard to handle. Consequently, just starting up a run can lead to significant material problems.

Landry Associates began as a small machine shop back in the 1970s. It has always believed in treating its workforce well, so it provides employees with paid breaks and lunches. The company loses 816 hours a year for holidays and vacations, which is part of the total idle time. Management tries to get the most out of its machines, however, so it changes them over often to run a new type of component. The orders themselves can be fairly small, ranging anywhere from 5,000 to 100,000 units of one component. Each time a new order is run, the machines have to be set up. In addition, they often run into material problems as the parts that go into making a component can be very small and hard to handle. Consequently, just starting up a run can lead to significant material problems.

REQUIRED:

Using the information in this table, help management answer the following questions. Suggestion: Generate a capacity report; it will help you answer these questions in an organized fashion.

a. What is the managed capacity cost per hour? Committed capacity cost per hour?

b. What is the estimated competitive capacity cost for a good unit?

c. What is the total cost of each of the nonproductive activities? What amount of the total costs is chargeable to idle capacity?

d. What are these costs on a per- unit basis?

e. What is the total average cost for making a good unit?

f. What recommendations would you make to management to improve profitability?

Step by Step Answer:

Managerial Accounting An Integrative Approach

ISBN: 9780999500491

2nd Edition

Authors: C J Mcnair Connoly, Kenneth Merchant