Acetone, a solvent used for cleaning of silicon wafers, is highly volatile with a vapor pressure of

Question:

The molecular weight of acetone is 58 g/gmole.

a. What is the total molar flow rate of liquid exiting the tower in units of kgmole/h at the conditions of operation?

b. Plot out the equilibrium line and operating line in mole fraction (yA vs. xA) coordinates. What is the minimum possible solvent flow rate into the tower from the standpoint of mass-transfer, in units of kgmole/h?

c. What is the height of packing required at the desired conditions of operation?

d. What is the gas flooding velocity of the AwesomepacktTM packing at the conditions of operation? Another engineer claims that Awesome pack packing is not really that awesome and suggests that 0.5-inch ceramic Intalox saddles might be better from a hydrodynamic point of view. What is the new gas flooding velocity? Is the 0.5-inch ceramic Intalox saddle packing better?

e. Is it possible that any acetone vapor in the air could condense at the conditions of the tower? Back up this answer with a calculation.

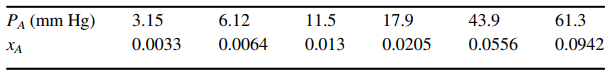

Equilibrium distribution data for acetone-water at 15°C

(A = acetone):

The word "distribution" has several meanings in the financial world, most of them pertaining to the payment of assets from a fund, account, or individual security to an investor or beneficiary. Retirement account distributions are among the most...

Step by Step Answer:

Fundamentals Of Momentum Heat And Mass Transfer

ISBN: 9781118947463

6th Edition

Authors: James Welty, Gregory L. Rorrer, David G. Foster