Mercedes-Benz All Activity Vehicle (AAV)* Introduction During the recession beginning in the early 1990s, Mercedes-Benz (MB) struggled

Question:

Mercedes-Benz All Activity Vehicle (AAV)*

Introduction

During the recession beginning in the early 1990s, Mercedes-Benz (MB) struggled with product development, cost efficiency, material purchasing, and problems in adapting to changing markets. In 1993, these problems caused the worst sales slump in decades, and the luxury car maker lost money for the first time in its history. Since then, MB has streamlined the core business, reduced parts and system complexity, and established simultaneous engineering programs with suppliers.

In their search for additional market share, new segments, and new niches, MB started developing a range of new products.New product introductions included the C-Class in 1993, the E-Class in 1995, the new sportster SLK in 1996, and the A-Class and M-Class All Activity Vehicle (AAV) in 1997. Perhaps the largest and most radical of MB’s new projects was the AAV. In April 1993, MB announced it would build its first passenger vehicle–manufacturing facility in the United States. The decision emphasized the company’s globalization strategy and desire to move closer to its customers and markets.

Mercedes-Benz United States International used function groups with representatives from every area of the company (marketing, development, engineering, purchasing, production, and controlling) to design the vehicle and production systems. A modular construction process was used to produce the AAV. First-tier suppliers provided systems rather than individual parts or components for production of approximately 65,000 vehicles annually.

The AAV Project Phases

The AAV moved from concept to production in a relatively short period of time. The first phase, the concept phase, was initiated in 1992. The concept phase resulted in a feasibility study that was approved by the board. Following board approval, the project realization phase began in 1993, with production commencing in 1997. Key elements of the various phases are described next.

Concept Phase, 1992–1993

Team members compared the existing production line with various market segments to discover opportunities for new vehicle introductions. The analysis revealed opportunities in the rapidly expanding sports utility vehicle market that was dominated by Jeep, Ford, and GM. Market research was conducted to estimate potential worldwide sales opportunities for a high-end AAV with the characteristics of a Mercedes-Benz. A rough cost estimate was developed that included materials, labor, overhead, and one-time development and project costs. Projected cash flows were analyzed over a 10-year period using net present value (NPV) analysis to acquire project approval from the board of directors. The sensitivity of the NPV was analyzed by calculating “what-if” scenarios involving risks and opportunities. For example, risk factors included monetary exchange rate fluctuations, different sales levels due to consumer substitution of the AAV for another MB product, and product and manufacturing costs that differed from projections.

On the basis of the economic feasibility study of the concept phase, the board approved the project and initiated a search for potential manufacturing locations. Sites located in Germany, other European countries, and the United States were evaluated. Consistent with the company’s globalization strategy, the decisive factor that brought the plant to the United States was the desire to be close to the major market for sports utility vehicles.

Project Realization Phase, 1993–1996

Regular customer clinics were held to view the prototype and to explain the new vehicle concept. These clinics produced important information about how the proposed vehicle would be received by potential customers and the press. Customers were asked to rank the importance of various characteristics, including safety, comfort, economy, and styling. Engineers organized in function groups designed systems to deliver these essential characteristics. However, MB would not lower its internal standards for components, even if initial customer expectations might be lower than the MB standard. For example, many automotive experts believed that the superior handling of MB products resulted from manufacturing the best automobile chassis in the world. Thus, each class within the MB line met strict standards for handling, even though these standards might exceed customer expectations for some classes. MB did not use target costing to produce the lowest price vehicle in an automotive class. The company’s strategic objective was to deliver products that were slightly more expensive than competitive models. However, the additional cost would have to translate into greater perceived value on the part of the customer.

Throughout the project realization phase, the vehicle (and vehicle target cost) remained alive because of changing dynamics. For example, the market moved toward the luxury end of the spectrum while the AAV was under development. In addition, crash test results were incorporated into the evolving AAV design. For these reasons, MB found it beneficial to place the design and testing team members in close physical proximity to other functions within the project to promote fast communication and decision making. Sometimes new technical features, such as side air bags, were developed by MB. The decision to include the new feature on all MB lines was made at the corporate level because experience had shown that customers’ reactions to a vehicle class can affect the entire brand.

Production Phase, 1997

The project was monitored by annual updates of the NPV analysis. In addition, a three-year plan (including income statements) was prepared annually and reported to the headquarters in Germany. Monthly departmental meetings were held to discuss actual cost performance compared with standards developed during the cost estimation process. Thus, the accounting system served as a control mechanism to ensure that actual production costs would conform to target (or standard) costs.

Target Costing and the AAV

The process of achieving target cost for the AAV began with an estimate of the existing cost for each function group. Next, components of each function group were identified with their associated costs. Cost reduction targets were set by comparing the estimated existing cost with the target cost for each function group. These function groups included the following: doors, sidewall and roof, electrical system, bumpers, power train, seats, heating system, cockpit, and front end. Next, cost reduction targets were established for each component. As part of the competitive benchmark process, MB bought and tore down competitors’ vehicles to help understand their costs and manufacturing processes.

The AAV manufacturing process relied on high-value-added systems suppliers. For example, the entire cockpit was purchased as a unit from a systems supplier. Thus, systems suppliers were part of the development process from the beginning of the project. MB expected suppliers to meet established cost targets. To enhance function group effectiveness, suppliers were brought into the discussion at an early stage in the process. Decisions had to be made quickly in the early stages of development.

The target costing process was led by cost planners who were engineers, not accountants. Because the cost planners were engineers with manufacturing and design experience, they could make reasonable estimates of costs that suppliers would incur in providing various systems. Also, MB owned much of the tooling, such as dies to form sheet metal, used by suppliers to produce components. Tooling costs are a substantial part of the one-time costs in the project phase.

Index Development to Support Target Costing Activities

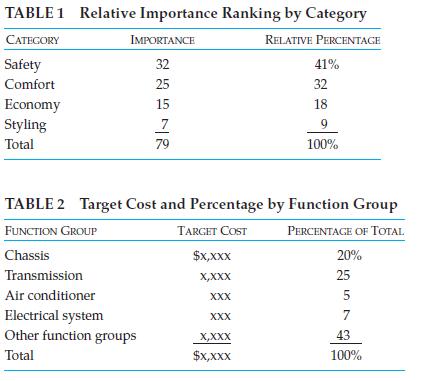

During the concept development phase, MB team members used various indexes to help them determine critical performance, design, and cost relationships for the AAV**. To construct the indexes, various forms of information were gathered from customers, suppliers, and their own design team. Although the actual number of categories used by MB was much greater, Table 1 illustrates the calculations used to quantify customer responses to the AAV concept. For example, values shown in the “Importance” column resulted from asking a sample of potential customers whether they consider each category extremely important when considering the purchase of a new MB product. Respondents could respond affirmatively to all categories that applied.

To gain a better understanding of the various sources of costs, function groups were identified together with target cost estimates. (MB also organizes teams called function groups whose role is to develop specifications and cost projections.) As shown in Table 2, the relative target cost percentage of each function group was computed.

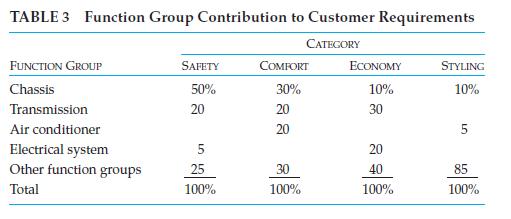

Table 3 summarizes how each function group contributes to the consumer requirements identified in Table 1. For example, safety was identified by potential customers as an important characteristic of the AAV; some function groups contributed more to the safety category than others. MB engineers determined that chassis quality was an important element of safety (50% of the total function group contribution).

Table 4 combines the category weighting percentages from Table 1 with the function group contribution from Table 3. The result is an importance index that measures the relative importance of each function group across all categories. For example, potential customers weighted the categories of safety, comfort, economy, and styling as 0.41, 0.32, 0.18, and 0.09, respectively. The rows in Table 4 represent the contribution of each function group to the various categories. The importance index for the chassis is calculated by multiplying each row value by its corresponding category value and summing the results: (0.50 × 0.41) + (0.30 × 0.32) + (0.10 × 0.18) + (0.10 × 0.09) = 0.33.

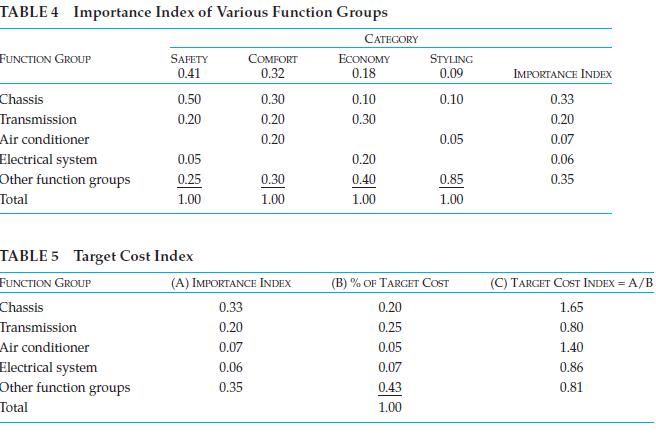

As shown in Table 5, the target cost index is calculated by dividing the importance index by the target cost percentage by function group. Managers at MB used indexes such as these during the concept design phase to understand the relationship of the importance of a function group to the target cost of a function group. Indexes less than 1 may indicate a cost in excess of the perceived value of the function group. Thus, opportunities for cost reduction consistent with customer demands, may be identified and managed during the early stages of product development. Choices

made during the project realization phase were largely irreversible during the production phase because approximately 80% of the production cost of the AAV was for materials and systems provided by external suppliers.

The AAV project used a streamlined management structure to facilitate efficient and rapid development. The streamlined MB organization produced an entirely new vehicle from concept to production in four years. Using the target costing process as a key management element, MB manufactured the first production AAV in 1997.

Required

(a) What is the competitive environment faced by MB as it considers launching the AAV?

(b) How has MB reacted to the changing world for luxury automobiles?

(c) Using Cooper’s cost, quality, and functionality chart***, discuss the factors on which MB would have to compete with other automobile producers, such as Jeep, Ford, and GM.

(d) How does the AAV project link with MB’s strategy in terms of market coverage?

(e) Explain the process of developing an importance index for a function group or component. How can such an index guide managers in making cost reduction decisions?

(f) How does MB approach cost reduction to achieve target costs?

(g) How do suppliers factor into the target costing process? Why are they so critically important to the success of the MB AAV?

(h) What role does the accounting department play in the target costing process?

*Institute of Management Accountants, Cases from Management Accounting Practice, Volume 15. Adapted with permission. The case author, Tom Albright, wishes to express his gratitude to Ola Kallenin's, Johnathan DeHart, Jason Hoff, Henrik Jonsson, Iosef Pfau, and Günther Thuss of Mercedes-Benz for their generous contributions to the development of this case.

**All numbers have been altered for proprietary reasons; however, the tables illustrate the actual process used in the development of the AAV.

***Robin Cooper, When Lean Enterprises Collide (Boston: Harvard Business School Press, 1995).

Step by Step Answer:

Management Accounting Information for Decision-Making and Strategy Execution

ISBN: 978-0137024971

6th Edition

Authors: Anthony A. Atkinson, Robert S. Kaplan, Ella Mae Matsumura, S. Mark Young