CDE has recently won a contract to supply a component to a major car manufacturer that is

Question:

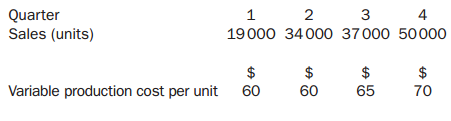

CDE has recently won a contract to supply a component to a major car manufacturer that is about to launch a new range of vehicles. This is a great success for the design team of CDE as the component has many unique features and will be an important feature of some of the vehicles in the range.CDE is currently building a specialized factory to produce the component. The factory will start production on 1 January.There is an expected demand for 140 000 units of the component.Forecast sales and production costs are:

Fixed production overheads for the factory are expected to be $2.8 million.A decision has to be made about the production plan. The choices are:Plan 1: Produce at a constant rate of 35 000 units per quarter Inventory would be used to cover fluctuations in quarterly demand. Inventory holding costs will be $13 per unit and will be incurred quarterly based on the average inventory held in each of the four quarters.Plan 2: Use a just-in-time (JIT) production system The factory would be able to produce 36 000 units per quarter in ?normal? time and up to a further 20 000 units in ?overtime?. However, each unit produced in ?overtime? would incur additional costs equal to 40 percent of the forecast variable production cost per unit for that quarter.

Required:(a) Produce calculations using the above data to show which of the two plans would incur the lowest total cost.(b) Explain TWO reasons why the decision about the production plan should not be based on your answer to part (a) alone.

Step by Step Answer: