Klump Trekkers, Inc., manufactures engines that are used in recreational equipment, such as motorcycles and personal watercraft.

Question:

Klump Trekkers, Inc., manufactures engines that are used in recreational equipment, such as motorcycles and personal watercraft. The company currently assembles the camshafts for these motors in its assembly department, which employs 40 skilled technicians. Due to crowded plant conditions and a shortage of skilled technicians, Klump is considering outsourcing the camshaft assembly to Mercury Motors, a specialist in the field. Mercury would supply 150,000 camshafts at a price of $80 each.

Mark Tobian is studying the proposed outsourcing deal and has prepared the following analysis.

Savings:

1. Reduction in assembly technicians ($32,500 X 35) . . . . . . . . . . . . . . . . . . . . . . . . . . . . $1,137,500

2. Supervisor transferred . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43,000

3. Purchasing clerk transferred . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24,000

4. Floor space savings 1(1,500 X $15) + (8,000 X $12)] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118,500

5. Reduced purchase orders (1,200 X $2.25) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2,700

Total savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . $1,325,700

Costs:

6. Increased component cost [150,000 X ($80.00 — $73.50)] . . . . . . . . . . . . . . . . . . . . . . . . . . . . 975,000

7. Hire junior engineer . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42,000

8. Hire quality control inspector . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38,000

9. Increased storage cost for safety stock (10% X 150,000 X $3.00) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45,000

Total costs . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1,100,000

Net annual savings . . . . . . . . . . . . . . . . . . . . . . . . . . . . $ 225,700

Additional information Tobian has gathered includes the following:

- Of the 40 technicians employed in the assembly department, 35 will be let go. Five technicians will be retained and transferred to the field service department to perform repair work. The supervisor of the assembly department will be transferred and promoted to assistant floor supervisor. No such position currently exists in the plant.

- Ajunior engineer will be hired to act as a liaison between Kiump and Mercury, to ensure technical conformity. A quality control inspector will be hired to monitor Mercury’s adherence to quality standards. The clerk in the purchasing department who handled all the camshaft purchasing will be transferred to an open clerical position in the sales department. Funds are available in the sales department to cover this position.

- The standard cost of producing a camshaft is as follows:

Direct materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . $30.00

Direct labor . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14.50

Variable manufacturing overhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.50

Fixed manufacturing overhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.50

Total cost . . . . . . . . . . . . . . . . . . . . . . . . . . . . $73.50

- The 8,000 square feet of space used by the assembly department will be converted to storage space. Currently, the space is valued at $12 per square foot. For the past year, Klump has been renting 1,500 square feet of storage space in a nearby building for $15.00 per square foot. This space will not be needed after the assembly department space is freed up.

- Management wants to increase safety stock levels from the current 5% of projected volume to 10% of projected volume. The variable cost to store the camshafts is $3.00 per camshaft.

- Klump will no longer need to issue the 1,200 purchase orders for camshaft materials. The variable cost of issuing a purchase order is $2.25.

Required

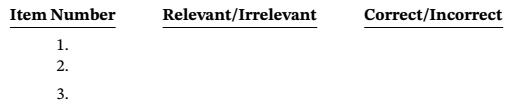

a. For each of the nine items listed in Tobian’s analysis, indicate whether the item should have been included in the analysis. If the item is not relevant to the analysis, explain why it should not have been included. For those items that are relevant to the analysis, indicate whether the amount Tobian included is correct or incorrect. Use the following format for your answer:

b. What would be the financial impact on Klump of outsourcing the camshaft assembly to Mercury?

c. What other factors should Klump consider before making the decision to outsource the camshaft assembly?

Step by Step Answer: