You need to plan the fabrication and assembly of an order of 40 side (accessory) tables due

Question:

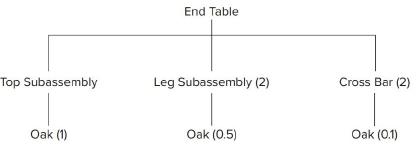

You need to plan the fabrication and assembly of an order of 40 side (accessory) tables due in six workdays. See the product structure tree that follows. The raw material is planks of oak measuring one inch by four inches by six feet long. The product structure tree below shows that one end table is made of one top sub-assembly, two leg sub-assemblies, and two cross-bars. One top sub-assembly is made from one plank of oak, one leg sub-assembly is made from 0.5 plank of oak, and one cross-bar is made of 0.1 plank of oak. The cutting and assembly time of one top subassembly is 20 minutes. The cutting and assembly time of one leg sub-assembly is 10 minutes. The cutting time to make one cross-bar is two minutes. Lastly, the final assembly of one end table is 15 minutes. Assume that the shop works eight hours a day, five days a week. The purchase lead time for oak is one workday. Assume that each operation is performed by a different worker in a different work centre and each batch is to be completed before it is moved to the next work centre. Assume lot-for-lot ordering for all items, except that oak is bought in a batch of 150 planks. There are no inventories on hand or on order, except for 40 planks of oak on hand. Also, there are no safety stocks required, except 30 planks of oak.

a. Determine each of the manufacturing lead times for this order (round up to whole days).

b. Develop the MRP tables. What action should you take now?

Step by Step Answer:

Operations Management

ISBN: 9781259270154

6th Canadian Edition

Authors: William J Stevenson, Mehran Hojati, James Cao