A trim heater is to be designed to heat (116,000 mathrm{lb} / mathrm{hr}) of (57 mathrm{wt} %)

Question:

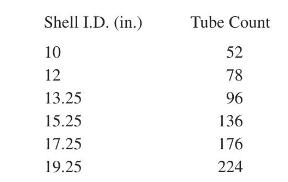

A trim heater is to be designed to heat \(116,000 \mathrm{lb} / \mathrm{hr}\) of \(57 \mathrm{wt} \%\) ethane, \(25 \mathrm{wt} \%\) propane, and \(18 \mathrm{wt} \%\) n-butane from 80 to \(96^{\circ} \mathrm{F}\). The stream will enter the exchanger at 520 psia and must not reach the bubble point in the exchanger. The stream will be heated with gasoline, which will enter at \(240^{\circ} \mathrm{F}\) and \(95 \mathrm{psia}\), with a flow rate of \(34,000 \mathrm{lb} / \mathrm{hr}\). Standard practice of the company is to use 1-2 shell-and-tube heat exchangers with 3/4-in., 16 BWG carbon steel tubes, \(20 \mathrm{ft}\) long, 1 -in. square pitch. Tube count depends on shell diameter, with the following diameters available:

The gasoline will flow on the shell side. Assume a combined fouling factor of 0.002 (hr-ft2-∘F)/Btu. Design a suitable heat exchange system, assuming a 25% overdesign factor.

Step by Step Answer:

Product And Process Design Principles Synthesis Analysis And Evaluation

ISBN: 9781119355243

4th Edition

Authors: Warren D. Seider, Daniel R. Lewin, J. D. Seader, Soemantri Widagdo, Rafiqul Gani, Ka Ming Ng