During vertical spindle surface grinding, adjustments are made on a multi-axis computer numerical control (CNC) machine by

Question:

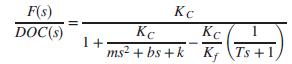

During vertical spindle surface grinding, adjustments are made on a multi-axis computer numerical control (CNC) machine by measuring the applied force with a dynamometer and applying appropriate corrections. This feedback force control results in higher homogeneity and better tolerances in the resulting finished product. In a specific experiment with an extremely high feed rate, the transfer function from the desired depth of cut (DOC) to applied force was

where k = 2.1 × 104 N/m; b = 0.78 Ns/m; m = 1.2 × 10-4 kg; KC = 1.5 × 104 N/mm; and T = 0.004s: The parameter Kf is varied to adjust the system. Find the range of Kf under which the system is stable (Hekman, 1999).

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Question Posted: