One of the breakthrough events for the development of BPM was Fords acquisition of a big financial

Question:

One of the breakthrough events for the development of BPM was Ford’s acquisition of a big financial stake in Mazda during the 1980s. When visiting Mazda’s plants, one of the things that Ford executives noticed was that units within Mazda seemed considerably understaffed in comparison with comparable units within Ford, yet operated normally. A famous case study illustrating this phenomenon, first narrated by Michael Hammer and subsequently analyzed by many others, deals with Ford’s purchasing process. This inspired what became known as Business Process Reengineering (BPR), which Hammer and Champy define as “the fundamental rethinking and radical redesign of business processes to achieve dramatic improvements in critical, contemporary measures of performance, such as cost, quality, service, and speed.”

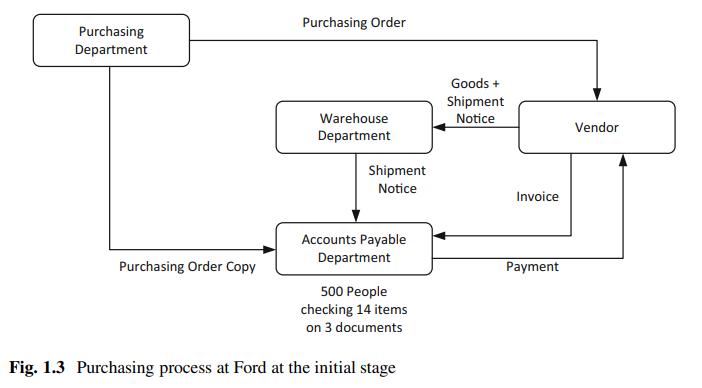

Figure 1.3 depicts the way purchasing was done within Ford at the time. Every purchase that Ford would make needed to go through the purchasing department. On deciding that a particular quantity of products indeed had to be purchased, this department sent out an order to the vendor in question. It would also send a copy of that order to accounts payable. When the vendor followed up, the ordered goods would be delivered at Ford’s receiving warehouse. Along with the goods came a shipping notice, which was passed on to accounts payable. The vendor would also send out an invoice to accounts payable directly.

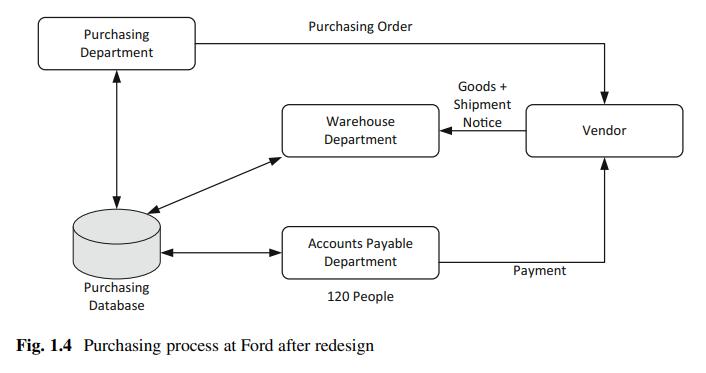

Against this background, it becomes clear that the main task of accounts payable was to check the consistency between three documents (purchase order copy, shipping notice, and invoice), each document consisting of roughly 14 data items (type of product, quantity, price, etc.). Not surprisingly, numerous discrepancies were discovered every day and sorting out these discrepancies occupied several hundred people within Ford. By contrast, at Mazda only five people worked in this department (as opposed to 500 people at Ford), while Mazda was not 100 times smaller than Ford in any relevant measure. Fundamentally, the problem is that Ford was detecting and resolving discrepancies one by one, while Mazda instead was avoiding the discrepancies in the first place. After a more detailed comparison with Mazda, Ford carried out several changes in its own purchasing process, which led to the redesigned process depicted in Figure 1.4........

Consider the purchasing process at Ford.

1. Who are the actors in this process?

2. Which actors can be considered as customers in this process?

3. What value does the process deliver to its customers?

4. What are the possible outcomes of this process?

Step by Step Answer:

Fundamentals Of Business Process Management

ISBN: 9783662565087

2nd Edition

Authors: Marlon Dumas, Marcello La Rosa, Jan Mendling, Hajo A. Reijers