In 2007, a group of students and faculty from Brigham Young University developed and took to Tonga

Question:

In 2007, a group of students and faculty from Brigham Young University developed and took to Tonga a process for using coconuts (available in plentiful supply) to produce biodiesel fuel and soap (both products of high value to the Tongan people).

The process consists of the following:

A. The coconuts are preprocessed (the preprocessing method doesn't need to be represented on the diagram) to produce coconut milk and "dry" coconut oil.

B. The coconut oil passes through an "Oil Heater" (fueltype) before entering a reactor (open-tank, stirred).

C. Methanol and a small amount of sodium hydroxide (NaOH, acting as a catalyst) are mixed together in a mixer (open-tank, stirred), and the resulting mixture also enters the reactor described in B.

D. In the reactor (described in B), the methanol and coconut oil react to form biodiesel and glycerol. Two streams leave the reactor: crude biodiesel (also containing some water and residuals) and glycerol (also containing unreacted methanol).

E. The crude biodiesel passes through a "washer" where water is sprayed into the stream (like a spray condenser), and a stream of water and residuals leaves the bottom of the washer. Meanwhile, the washed (wet) biodiesel leaves the washer and passes through a water filter, which removes most of the water.

F. The biodiesel finally enters a 2-stage evaporator. Stage 1 is a "Diesel Heater" (fuel-type) that warms the biodiesel, which then enters Stage 2, a "Water Evaporator" tank (horizontal tank) where the water vapor evaporates and exits from the top, while the dry diesel exits the bottom.

G. The glycerol stream from the reactor (described in D) enters a 2-stage evaporator. Stage 1 is a "Glycerol Heater" (fuel-type) that warms the glycerol stream, which then enters Stage 2, a "Methanol Evaporator" tank (horizontal tank) where the methanol vapor evaporates and exits from the top, while the purified glycerol exits the bottom.

H. The purified glycerol from G enters a Solidifier (open tank, mixed). Also entering the Solidifier is some salt (NaCl) solution (a solidifying agent) and some of the coconut milk (described in A). From the Solidifier comes the solid soap.

I. The methanol vapor leaving the Methanol Evaporator (described in G) passes through a "Methanol Condenser" (coil-in-tank), with a cold-water stream providing the cooling. The condensed methanol leaving the condenser is returned to make up part of the methanol stream entering the mixer described in C.

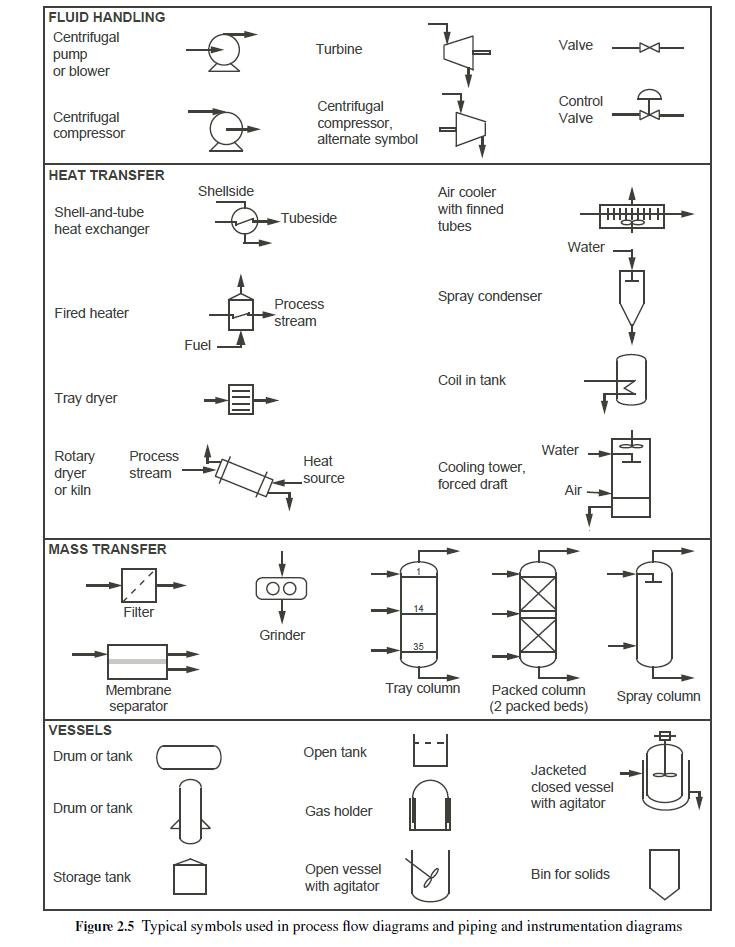

Construct a pictorial Process Flow Diagram (without the stream table) using the symbols given in Figure 2.5.

Step by Step Answer:

Introduction To Chemical Engineering Tools For Today And Tomorrow

ISBN: 9780470885727

5th Edition

Authors: Kenneth A. Solen, John N. Harb