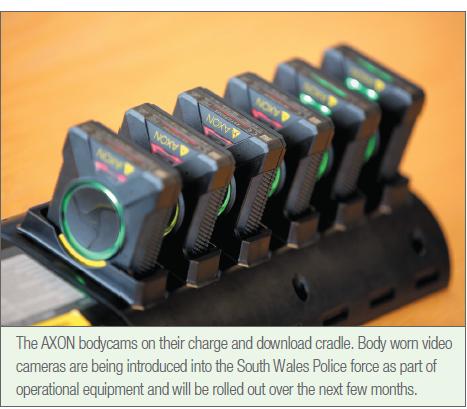

Protect life. Protect truth. That's the mission of Axon, the company that produces public safety technologies such

Question:

Protect life. Protect truth. That's the mission of Axon, the company that produces public safety technologies such as Taser electrical smart weapons and body cameras for law enforcement around the globe. In business since 1993, the company manufactures three weapons lines inside its high-tech headquarters in Scottsdale, Arizona. Ninety-nine percent of its customers are in law enforcement, military, correctional, and professional security organizations.

Designing and manufacturing smart weapons technologies requires precise engineering and production processes that can ensure both accuracy and operational safety for its organizational customers and personal protection buyers. This attention to detail is evidenced in the company's commitment to quality, and can be seen in the way the manufacturing operation is organized.

Axon's manufacturing operations are ISO 9001:2008 certified.

All finished goods are produced to stock, so that the company can be responsive when an order is received. Sales history data help dictate which items to make to stock, and which could sit in inventory between 6 and 12 weeks before being sold. Most employees have undergone voluntary exposure to the weapons, including the founders.

Axon's work cells are arranged by product. At the start of the week, each cell is given a "production order" document that lists the bill of materials for the finished goods that cell must produce during the week. The production order is released by Axon's Enterprise Resource Planning (ERP) system, with raw materials required for assembly pulled and staged at each cell weekly. In addition to supporting the informational needs of all the functional areas of a firm, ERP systems support the manufacture of a firm's products by scheduling the fabrication of components and the arrival of purchased materials in support of the overall production plan.

Axon's attention to quality is embedded throughout its manufacturing processes. Raw materials are tested and inspected for quality conformance at the supplier to be certain no faulty components are shipped. Circuit boards, which are assembled domestically, are each tested prior to shipment, and then acceptance sampling at Axon's receiving dock confirms shipment conformance.

The same process occurs for the supplier of injection molded components, such as weapons casings. Testing includes functionality checks, drop tests to ensure the product can withstand being dropped, and temperature checks to make sure the weapons will work between a temperature range of -20 degrees Celsius and +50 degrees Celsius. When finished goods are ready, Axon performs a final quality assurance check on 100% of goods to ensure everything functions properly prior to shipping to the customer. All goods come with a 1-year warranty.

In 2009, 25 company managers from engineering, manufacturing, R&D, and quality assurance enrolled in a Six Sigma Green Belt training program offered at a nearby university. While the coursework was meaningful, Axon faced intense pressure to bring new products to market, due to which management focus on implementing Six Sigma principles waned. It wasn't until 2011 that Axon would again revisit its Six Sigma journey with renewed interest.

Management broadened the employee base to be trained, including customer service and marketing divisions, and chose to incorporate more stringent Six Sigma methodologies into its training. Six Black Belts emerged with projects targeted to strengthen operations at the company. One such project, initiated by Vice President of Manufacturing Bill Denzer, took aim at the softer side of production: its employees. Bill saw a need to empower manufacturing line employees with data so that they could take greater ownership of what was occurring within their environments. Although Axon collected manufacturing data daily for continuous improvement purposes prior to 2011, line level employees weren't involved in the analysis and problem solving required to rapidly change or fix issues. The manufacturing engineering group reviewed the data only after problems emerged, taking some time to investigate and resolve even as production tried to continue.

Bill's project sought to engage manufacturing engineering in the automation of test data collection to develop baselines for processes and establish upper and lower control limits. Line workers were given explicit parameters for processes, and they immediately took ownership of those processes. As a result, it quickly became evident when something in the work cell was trending out of control so the issue could be resolved within hours. A formal escalation process further ensured that the right individuals were notified to get action.

In 2013, Axon installed computer monitors above each work cell so that all manufacturing employees could see the data related to how they were doing. The data include scrap dollars as a percentage of total production, process yield (units produced), average labor cost per unit compared to expected labor cost, average material costs per unit compared to expected material costs, daily/monthly/quarterly production output compared to planned output, throughput times compared to standards, and more.

To close the loop on data collection and performance analysis, Axon holds daily meetings at the start of each shift to review the metrics. In addition, the Axon Continuing Improvement program, or TCI, was created. This program generates over 15 suggestions weekly from employees across all areas of the manufacturing process. Bulletin boards in each work cell make it easy to write up issues, and the visibility of the suggestions gets immediate attention.

Further, anyone can stop production if a problem is detected, and issues get resolved within hours instead of days or weeks, leading to reduced downtime and quality problems.

QUESTIONS

1. Implementing Six Sigma programs takes considerable time and commitment from an organization. Evaluate Axon's efforts with regard to management commitment, measurement systems to track progress, tough goal setting, education, communication, and customer priorities.

2. How might Axon's commitment to employee engagement help the company avoid the four costs of poor process performance and quality (prevention, appraisal, internal failure, external failure)?

3. Describe Axon's total quality management approach as it relates to customer satisfaction, employee involvement, and continuous improvement.

Step by Step Answer:

Operations Management Processes And Supply Chains

ISBN: 9781292409863

13th Global Edition

Authors: Lee Krajewski, Naresh Malhotra, Larry Ritzman