Martin manufacturing company uses a piece of machinery that has three different bushings that periodically fail in

Question:

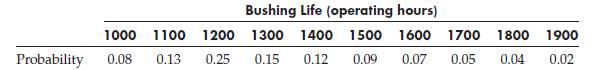

Martin manufacturing company uses a piece of machinery that has three different bushings that periodically fail in service. The probability distribution of the life of each bushing is identical and is summarized by the following table.

When a bushing fails, the machine stops, a repair person is called, and a new bushing is installed. Each bushing costs $35. Downtime for the machine costs the company an estimated $15 per minute. The direct on-site cost for the repair person is $50 per hour. The amount of time required for the repair person to arrive after a bushing fails is approximately normally distributed with a mean of 10 minutes and standard deviation of 2 minutes. The amount of time required to change a bushing follows a triangular distribution with minimum, most likely, and maximum values of 15, 20, and 30 minutes, respectively.

a. On average, what is the total bushing-related cost that Martin incurs to operate this machine for 20,000 hours?

b. Martin is considering implementing another repair policy: if any of the bushings fail, all three are replaced. What is the total bushing-related cost that Martin incurs to operate this machine for 20,000 hours under this policy?

c. Should Martin implement the new policy?

Step by Step Answer:

Spreadsheet Modeling & Decision Analysis A Practical Introduction to Management Science

ISBN: 978-0324656633

5th edition

Authors: Cliff T. Ragsdale