StayFresh, a manufacturer of refrigerators in India, has two plantsone in Mumbai and the other in Chennai.

Question:

StayFresh, a manufacturer of refrigerators in India, has two plants—one in Mumbai and the other in Chennai. Each plant has an annual capacity of 300,000 units. The two plants serve the entire country, which is divided into four regional markets: the north, with a demand of 100,000 units; the west, with a demand of 150,000 units; the south, with a demand of 150,000 units; and the east, with a demand of 50,000 units. Two other potential sites for plants include Delhi and Kolkata.

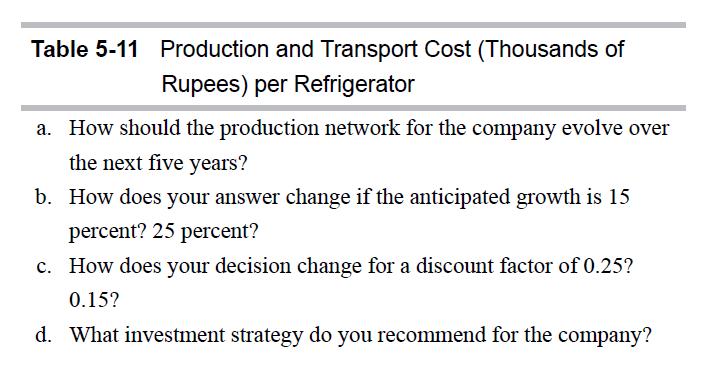

The variable production and transport costs (in thousands of rupees; 1 U.S. dollar is worth about 65 rupees) per refrigerator from each potential production site to each market are as shown in Table 5-11.

StayFresh is anticipating a compounded growth in demand of 20 percent per year for the next five years and must plan its network investment decisions. Demand is anticipated to stabilize after five years of growth. Capacity can be added in increments of either 150,000 or 300,000 units. Adding 150,000 units of capacity incurs a one-time cost of 2 billion rupees, whereas adding 300,000 units of capacity incurs a one-time cost of 3.4 billion rupees. Assume that StayFresh plans to meet all demand (prices are sufficiently high) and that capacity for each year must be in place by the beginning of the year. Also assume that the cost for the fifth year will continue for the next 10 years—that is, years 6 to 15. The problem can now be solved for different discount factors. To begin with, assume a discount factor of 0.2—that is, 1 rupee spent next year is worth 1 – 0.2 = 0.8 rupee this year.

Step by Step Answer:

Supply Chain Management Strategy Planning And Operation

ISBN: 9781292257891

7th Global Edition

Authors: Sunil Chopra