Assume that a division of Bose makes an electronic component for its speakers. Its manufacturing process for

Question:

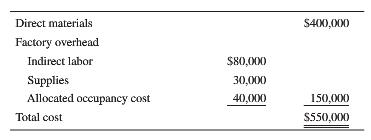

Assume that a division of Bose makes an electronic component for its speakers. Its manufacturing process for the component is a highly automated part of a just-in-time production system. All labor is considered to be an overhead cost, and all overhead is regarded as fixed with respect to output volume. Production costs for 100,000 units of the component are as follows:

A small, local company has offered to supply the components at a price of $4.20 each. If the division discontinued its production of the component, it would save two-thirds of the supplies cost and $30,000 of indirect-labor cost. All other overhead costs would continue.

The division manager recently attended a seminar on cost behavior and learned about fixed and variable costs. He wants to continue to make the component because the variable cost of $4.00 is below the $4.20 bid.

1. Compute the relevant cost of (a) making and (b) purchasing the component. Which alternative is less costly and by how much?

2. What qualitative factors might influence the decision about whether to make or to buy the component?

Step by Step Answer:

Introduction to Management Accounting

ISBN: 978-0133058789

16th edition

Authors: Charles Horngren, Gary Sundem, Jeff Schatzberg, Dave Burgsta