Many manufacturing companies in the United States and abroad use molded parts as components of a process.

Question:

Many manufacturing companies in the United States and abroad use molded parts as components of a process. Shrinkage is often a major problem. Thus a molded die for a part is built larger than nominal to allow for part shrinkage. In an injection molding study it is known that the shrinkage is influenced by many factors, among which is the injection velocity in ft/sec and mold temperature in °C. The following two data sets show the results of a designed experiment in which injection velocity held at two levels (say "low" and "high") and mold temperature was held constant at a "low" level. The shrinkage is measured in cm X 104.

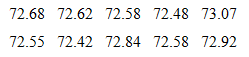

Shrinkage values at low injection velocity:

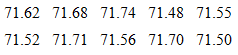

Shrinkage values at high injection velocity:

(a) Construct a dot plot of both data sets on the same graph. Indicate on the plot both shrinkage means, that for low injection velocity and high injection velocity.

(b) Based on the graphical results in (a), using the location of the two means and your sense of variability, what is your conclusion regarding the effect of injection velocity on shrinkage at "low" mold temperature?

Step by Step Answer:

Probability & Statistics For Engineers & Scientists

ISBN: 9780130415295

7th Edition

Authors: Ronald E. Walpole, Raymond H. Myers, Sharon L. Myers, Keying