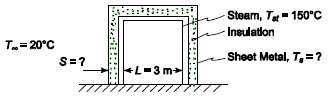

A gas-fired industrial furnace is used to generate steam. The furnace is a 3 m cubic structure

Question:

A gas-fired industrial furnace is used to generate steam. The furnace is a 3 m cubic structure and the interior surfaces are completely covered with boiler tubes transporting pressurized wet steam at 150°C. It is desired to keep the furnace losses to 1% of the total heat input of 1 MW. The outside of the furnace can be insulated with a blanket-type mineral wool insulation [k = 0.13 W/(m °C)], which is protected by a polished metal sheet outer shell. Assume the floor of the furnace is insulated. What is the temperature of the metal shell sides? What thickness of insulation is required?

GIVEN

An insulated cubic furnace with steam filled tubes on the inner walls

Steam temperature (Tst) = 150°C

Length of a side of the furnace (L) = 3 m

Thermal conductivity of mineral wool insulation (ki) = 0.13 W/(m°C)

Insulation is protected by metal sheet outer shell

Furnace losses (qc) = 1% of total heat input

Total heat input (qin) = 1 MW = 106 W

ASSUMPTIONS

Steady state operation

Thermal resistance of the convection within the steam pipes, the steam pipe walls, the furnace walls, and the metal shell negligible compared to that of the insulation

Air outside the furnace is still

The floor is well insulated'heat loss is negligible

Temperature of the metal shell is uniform

Ambient temperature (T???) = 20°C (293 K)

Edge effects are negligible

The emissivity of the polished metal shell (ε) = 0.05 (see Table9.2)

Step by Step Answer:

Principles of heat transfer

ISBN: 978-0495667704

7th Edition

Authors: Frank Kreith, Raj M. Manglik, Mark S. Bohn