Question: A shell-and-tube counterflow heat exchanger is to be designed for heating an oil from 80 to 180?F. The heat exchanger has two tube passes and

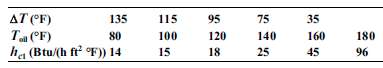

A shell-and-tube counterflow heat exchanger is to be designed for heating an oil from 80 to 180?F. The heat exchanger has two tube passes and one shell pass. The oil is to pass through 1 1/2-in. schedule 40 pipes at a velocity of 2000 fpm and steam is to condense at 215?F on the outside of the pipes. The specific heat of the oil is 0.43 Btu/(lb ?F) and its mass density is 58 lb/cu ft. The steam-side heat transfer coefficient is approximately 1800 Btu/(h ft2 ?F), and the thermal conductivity of the metal of the tubes is 17 Btu/ (h ft ?F). The results of previous experiments giving the oil-side heat transfer coefficients for the same pipe size at the same oil velocity as those to be used in the exchanger are shown below(a) Find the overall heat transfer coefficient U, based on the outer surface area at the point where the oil is 100?F,(b) Find the temperature of the inside surface of the pipe when the oil temperature is 100?F.(c) Find the required length of the tube bundle.GIVENA shell-and-tube counterflow heat exchanger - oil in tubes, steam is shellOil temperaturesTo,in = 80?FTo,out = 180?FTubes: 1.5 in. schedule 40 pipesOil velocity (Vo) = 200 ft/min = 12,000 ft/hSteam temperature (Ts) = 215?FOil specific heat (cpo) = 0.43 Btu/(lb ?F)Oil density (r) = 58 lb/ft3Steam side heat transfer coefficient (hs) = 1800 Btu/(h ft2 ?F)Thermal conductivity of the tube material (kt) = 17 Btu/(h ft ?F)Experimental data above was taken at the same oilvelocity

AT (CF) Ta (CF) ha (Btu/(h ft F)) 14 95 35 75 115 115 135 180 140 25 80 100 120 18 160 45 96 96 15

Step by Step Solution

3.49 Rating (162 Votes )

There are 3 Steps involved in it

a The overall heat transfer coefficient based on the outside tube ... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

66-E-M-E-H-M-T (1874).docx

120 KBs Word File