Question: Corrosion fatigue in metals has been defined as the simultaneous action of cyclic stress and chemical attack on a metal structure. A widely used technique

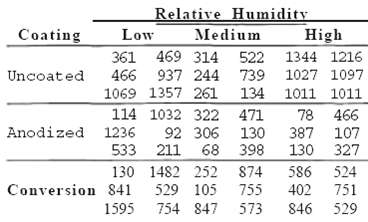

Corrosion fatigue in metals has been defined as the simultaneous action of cyclic stress and chemical attack on a metal structure. A widely used technique for minimizing corrosion-fatigue damage in aluminum involves the application of a protective coating. In a study conducted by the Department of Mechanical Engineering at the Virginia Polytechnic Institute and State University, different levels of humidity-Low: 20-25% relative humidityMedium: 55-60% relative humidityHigh: 86-91% relative humidity and 3 types of surface coatingsUncoated: no coatingAnodized: sulfuric acid anodic oxide coatingConversion: chromate chemical conversion coating was used. The corrosion-fatigue data, expressed in thousands of cycles to failure, were recorded as follows:(a) Perform an analysis of variance with a = 0.05 to test for significant main and interaction effects.(b) Use Duncan's multiple-range test at the 0.05 level of significance to determine which humidity level result in different corrosion-fatiguedamage.

Relative Humidity Medium Coating Low High 361 469 314 522 1344 1216 466 937 244 739 1027 1097 1069 1357 261 134 1011 1011 Uncoated 114 1032 322 471 92 306 533 211 68 398 78 466 107 387 130 327 Anodized 1236 130 130 1482 252 874 586 402 846 524 Conversion 841 529 105 755 751 1595 754 847 573 529

Step by Step Solution

3.34 Rating (166 Votes )

There are 3 Steps involved in it

a The hypotheses of the three parts are Source of Variation 001 Critical regions for Ho f 3... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

18-M-S-F-E (69).docx

120 KBs Word File