Question: A heat recovery device involves transferring energy from the hot flue gases passing through an annular region to pressurized water flowing through the inner tube

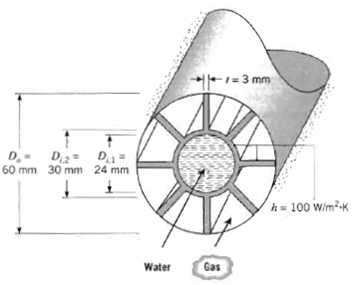

A heat recovery device involves transferring energy from the hot flue gases passing through an annular region to pressurized water flowing through the inner tube of the annulus. The inner tube has inner and outer diameters of 24 and 30 mm and is connected by eight struts to an insulated outer tube of 60-mm diameter. Each strut is 3 mm thick and is integrally fabricated with the inner tube from carbon steel (k = 50 W/m ∙ K). Consider conditions for which water at 300 K flows through the inner tube at 0.161 kg/s while flue gases at 800 K flow through the annulus, maintaining a convection coefficient of 100 W/m2 ∙ K on both the struts and the outer surface of the inner tube. What is the rate of heat transfer per unit length of tube from gas to the water?

a = = 3 mm D.- D2= D1= D1 = 24 mm 60 mm 30 mm h= 100 Wim*-K Gas Water

Step by Step Solution

3.42 Rating (168 Votes )

There are 3 Steps involved in it

KNOWN Geometry of finned annular heat exchanger Gasside temperature and convection coefficient Water... View full answer

Get step-by-step solutions from verified subject matter experts

Document Format (1 attachment)

8-E-M-E-H-M-T (1003).docx

120 KBs Word File