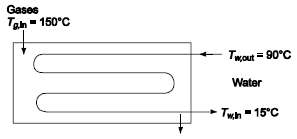

It is proposed to preheat the water for a boiler with flue gases from the boiler stack.

Question:

It is proposed to preheat the water for a boiler with flue gases from the boiler stack. The flue gases are available at 150?C, at the rate of 0.25 kg/s and specific heat of 1000 J/(kg K). The water entering the exchanger at 15?C at the rate of 0.05 kg/s is to be heated at 90?C. The heat exchanger is to be of the reversed current type, one shell pass and 4 tube passes. The water flows inside the tubes which are made of copper (2.5 cm-ID, 3.0 cm- OD). The heat transfer coefficient at the gas side is 115 W/(m2 K), while the heat transfer coefficient on the water side is 1150 W/(m2 K). A scale on the water side offers an additional thermal resistance of 0.002 (m2 K)/W.(a) Determine the overall heat transfer coefficient based on the outer tube diameter.(b) Determine the appropriate mean temperature difference for the heat exchanger.(c) Estimate the required tube length.(d) What would be the outlet temperature and the effectiveness if the water flow rate would be doubled, giving a heat transfer coefficient of 1820 W/(m2 K)?GIVENReverse current heat exchanger - 1 shell pass , 4 tube passesWater in tubes, flue gases in shellCopper tubesInside diameter (Di) = 2.5 cm = 0.025 mOutside diameter (Do) = 3.0 cm = 0.03 mSpecific heat of gases (cpg) = 1000 J/(kg K)Gas inlet temperatureTg,in = 150?CWater temperaturesTw,in = 15?CTw,out = 90?CGas flow rate (mg) = 0.25 kg/sWater flow rate (mw) = 0.05 kg/sTubes are copperGas side heat transfer coefficient (hc) = 115 W/(m2 K)Water side heat transfer coefficient (hi ) = 1150 W/(m2 K)Scaling resistance on the water side (Ri) = 0.002 (m2K)/W

Step by Step Answer:

Principles of heat transfer

ISBN: 978-0495667704

7th Edition

Authors: Frank Kreith, Raj M. Manglik, Mark S. Bohn